Assembly Fixture

The same vendor who provided quotes for the poster and package also provided some input on the assembly of the product, indicating that it would be time-consuming (and thus costly) to assemble the package in the U.S. To speed up the assembly process, we designed and fabricated a small assembly jig capable of winding all four strings onto the package simultaneously. Produced from just a handful of 3D printed and purchased parts, this jig vastly reduced the time it takes to assemble these units.

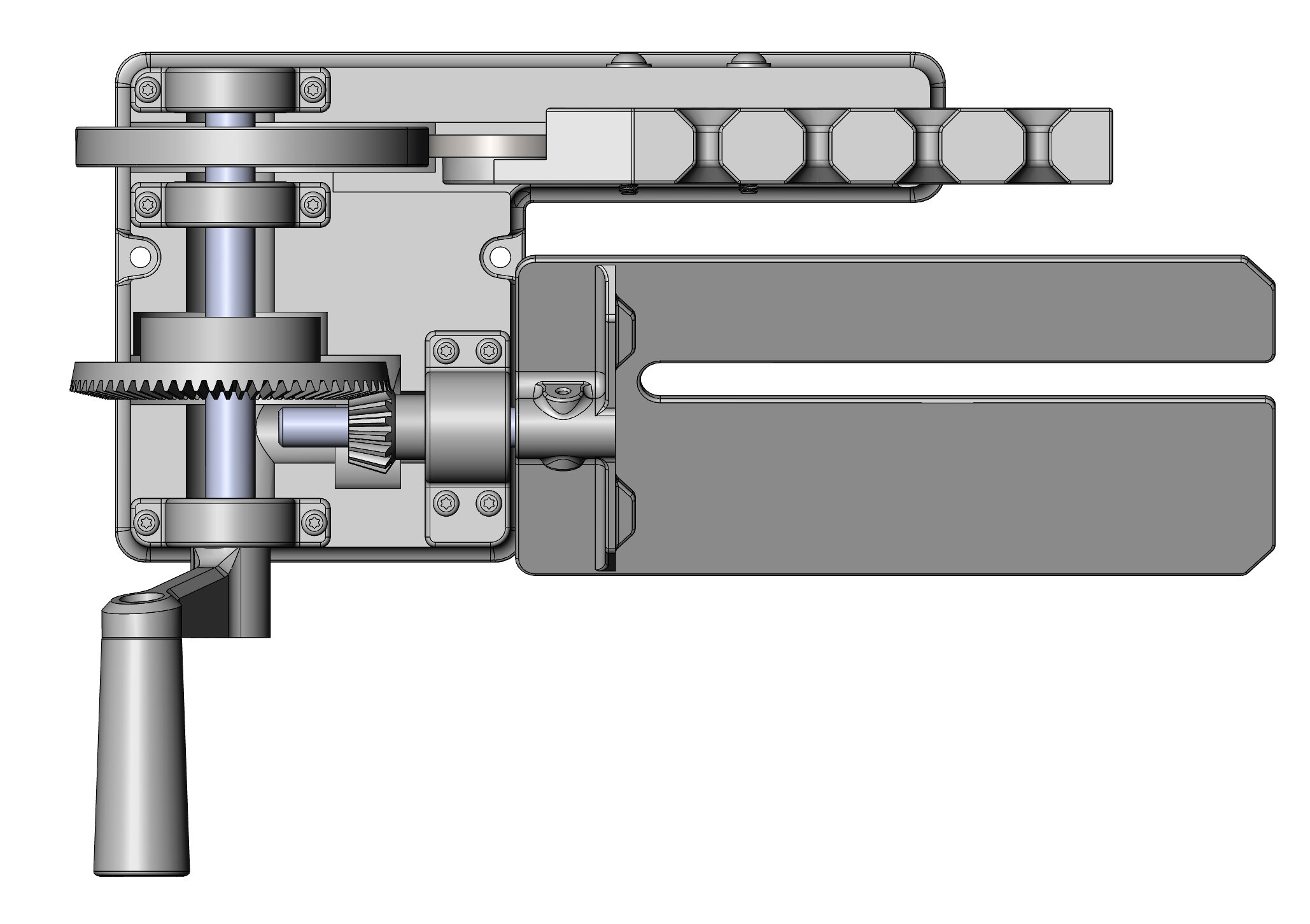

CAD Design

The screenshots below show the design of the jig, in Solidworks. To reduce the cost of producing potentially dozens of jigs, even bevel gears were printed on our in-house Lulzbot.

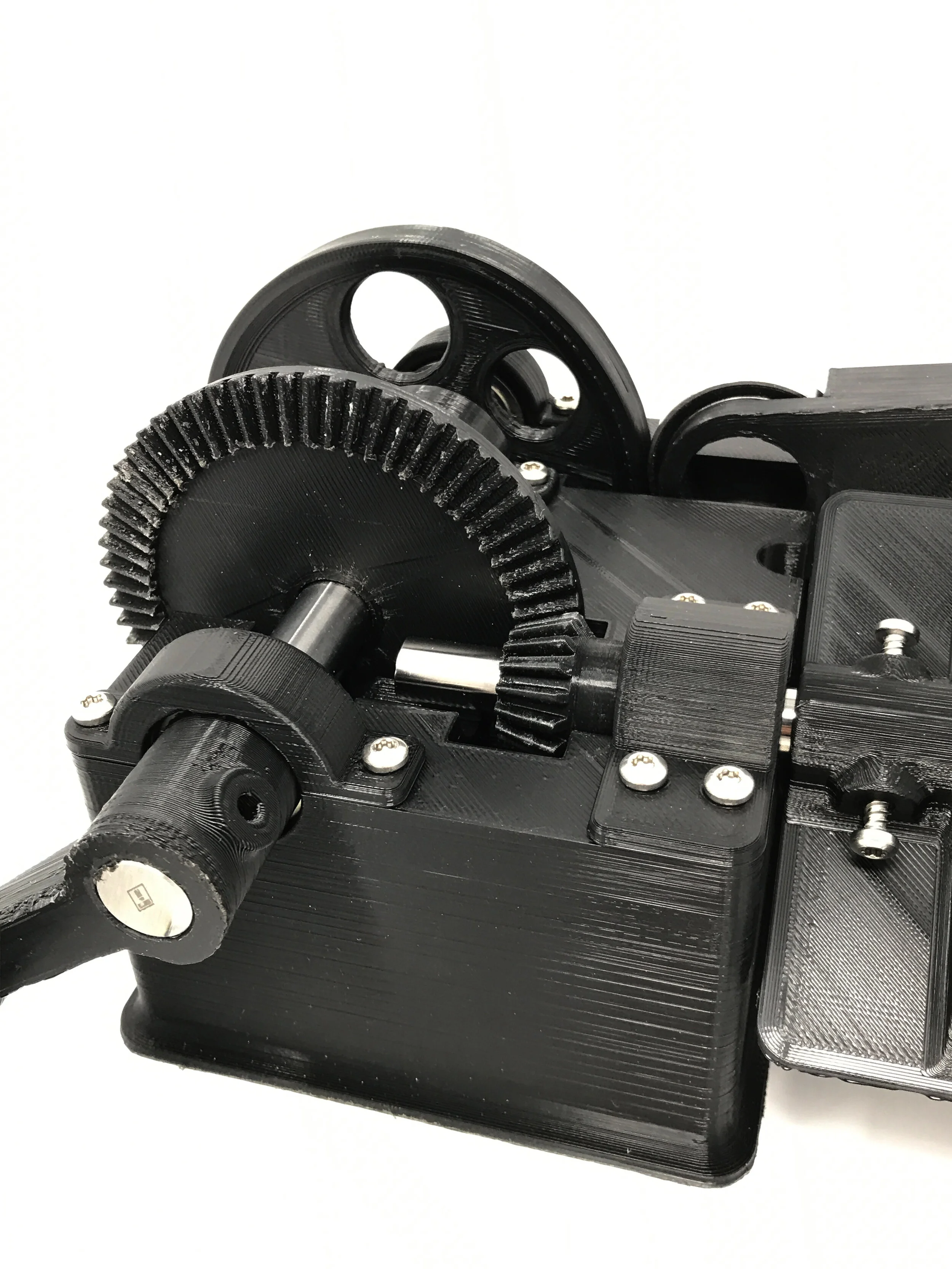

3D-Printed Winding Jig

The 3D printed result contains just a few purchased components from McMaster-Carr. 90% of the design is 3D printed.

Action!

This simple jig shuttles the cord as it winds it onto the package. The unit vastly reduces the time and difficulty of assembling these packages.

Designed for a cash-strapped startup, this simple winding jig is made from just a handful of 3D-printed and purchased components.