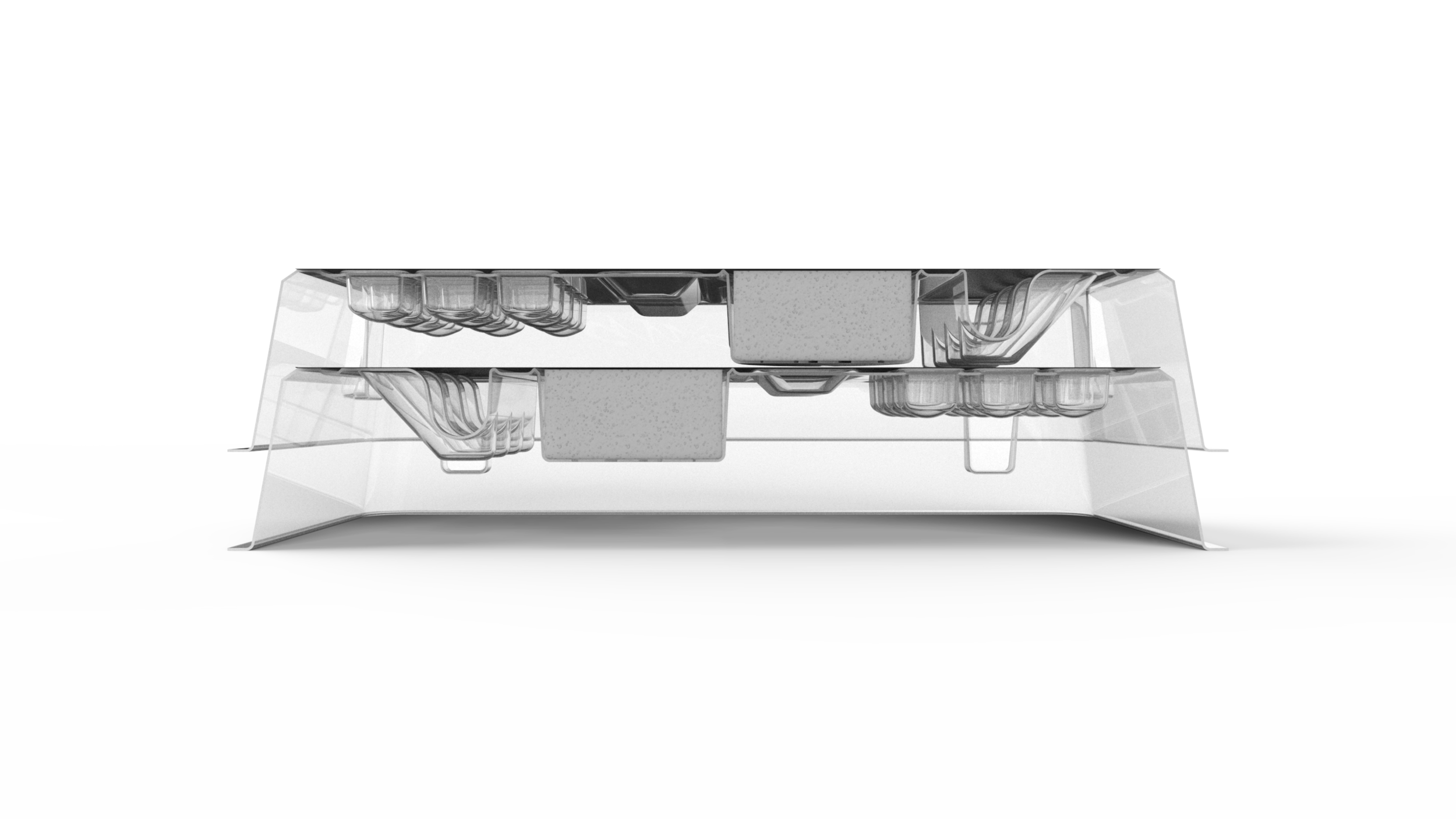

Tattoo Setup Tray for Ghost

This is the type of project we love the most. It demonstrates how our rapid, collaborative approach to product development can be used to turn the insights of an independent user-inventor into a marketable product quickly and at low cost. This was a rapid concept design and development program for Ghost — a team of brilliant artists and innovators who are disrupting the way tattoo artists purchase, inventory and use their supplies.

For tattoo artists, maintaining sanitary working conditions and supply levels are critical aspects of their work. In 2019, the founders of Ghost saw an opportunity to enhance both the safety and the logistics of the tattoo artist’s profession. In less than a year, these innovators have disrupted the way tattooists purchase, inventory and use their supplies.

PRoject Background

This project centered on the challenges a tattoo artist faces both in maintaining sterility and managing supply logistics. With their experience as logistics expert, tattoo artist and piercer, founders Bryan Kilby, Krist Karloff and Russell Van Schaick saw an opportunity to address both of these needs with a single, innovative design.

Sterility

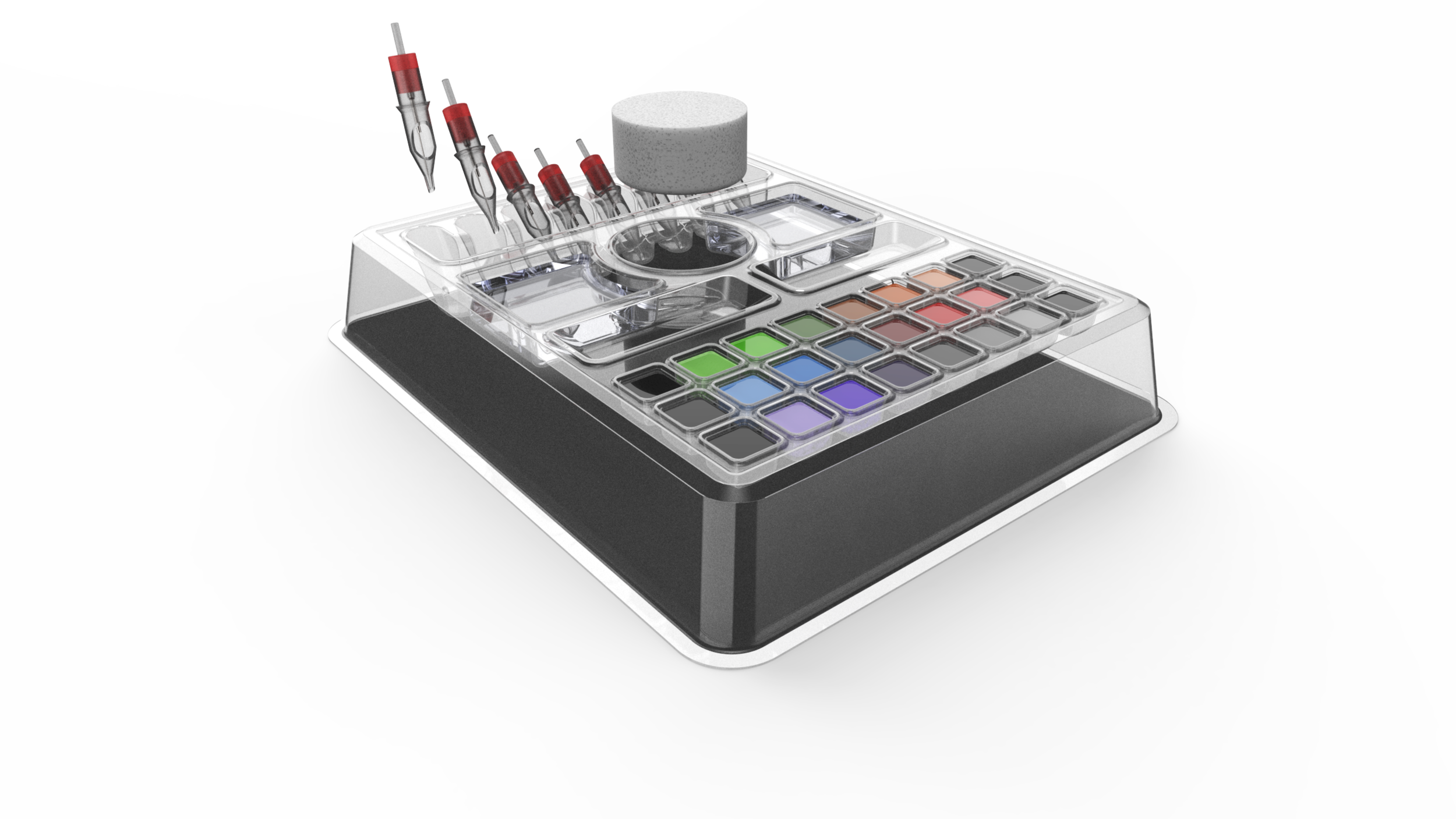

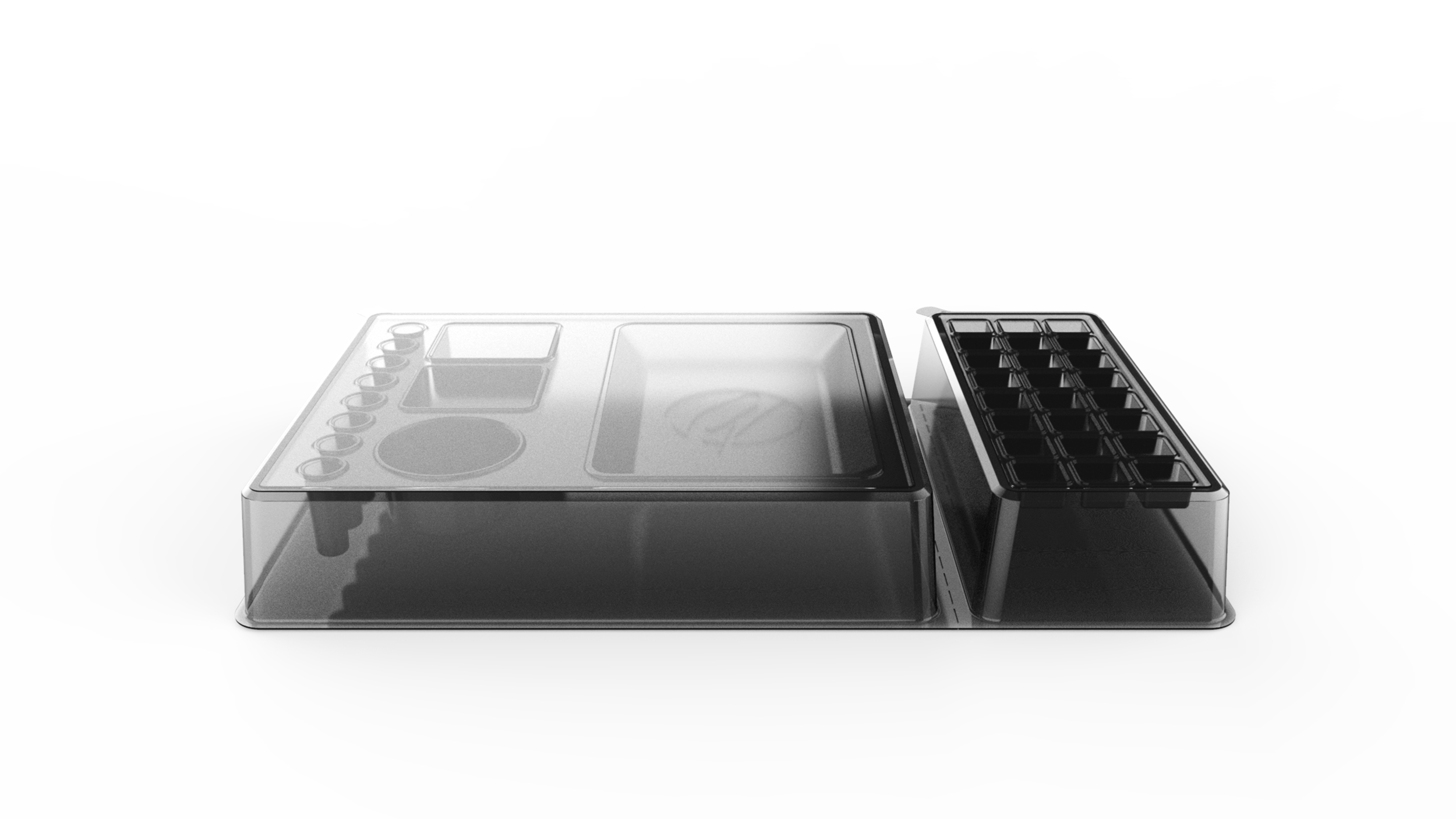

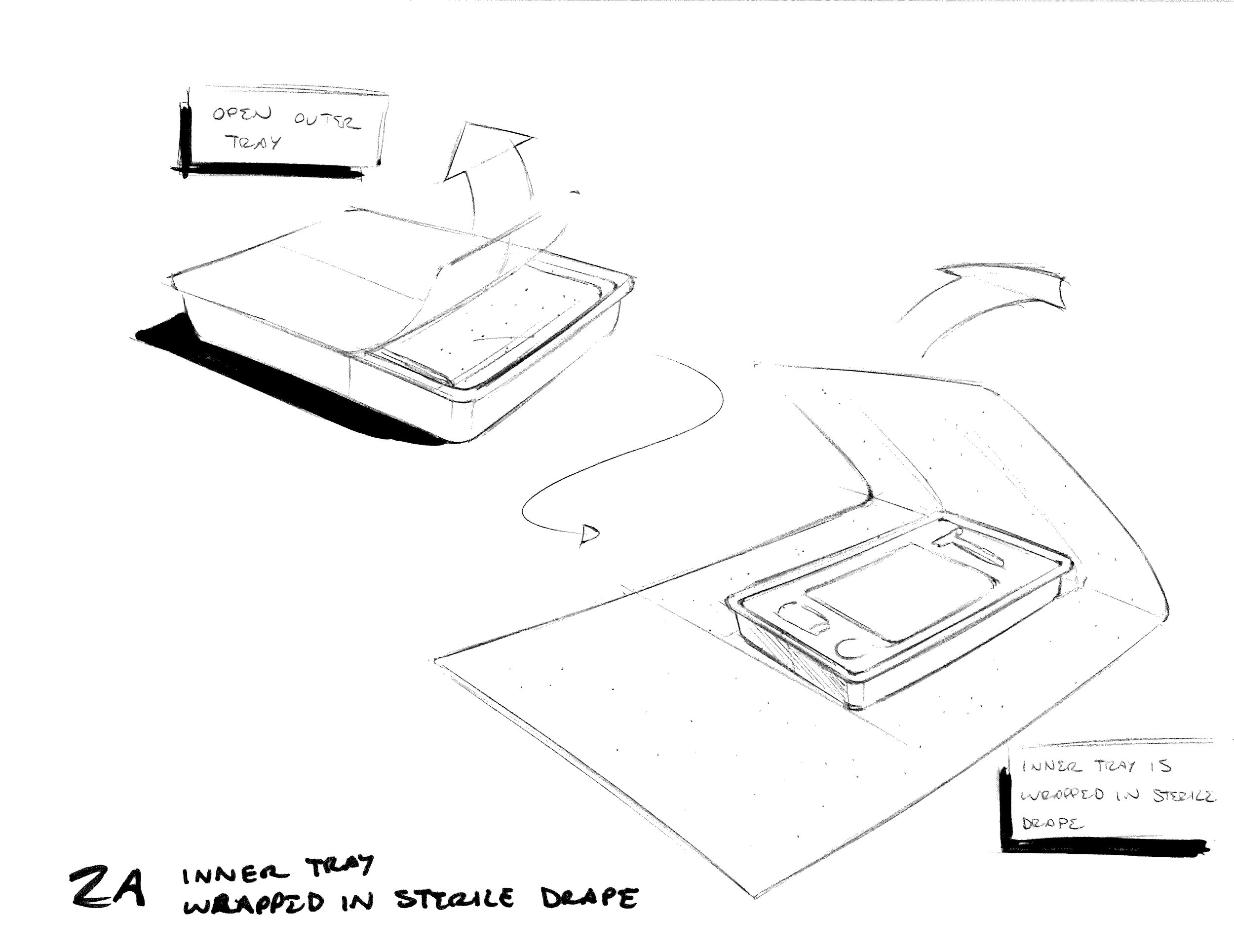

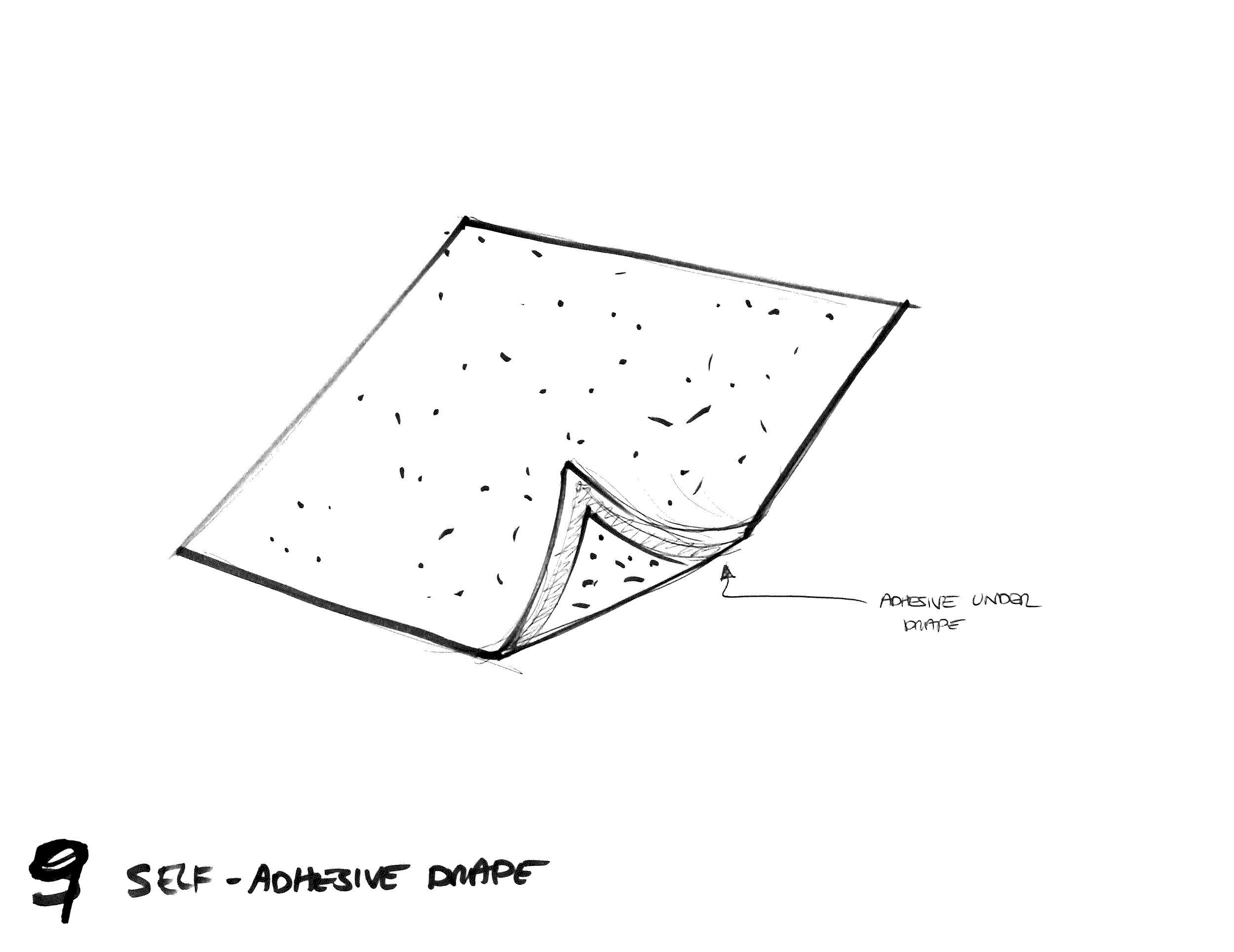

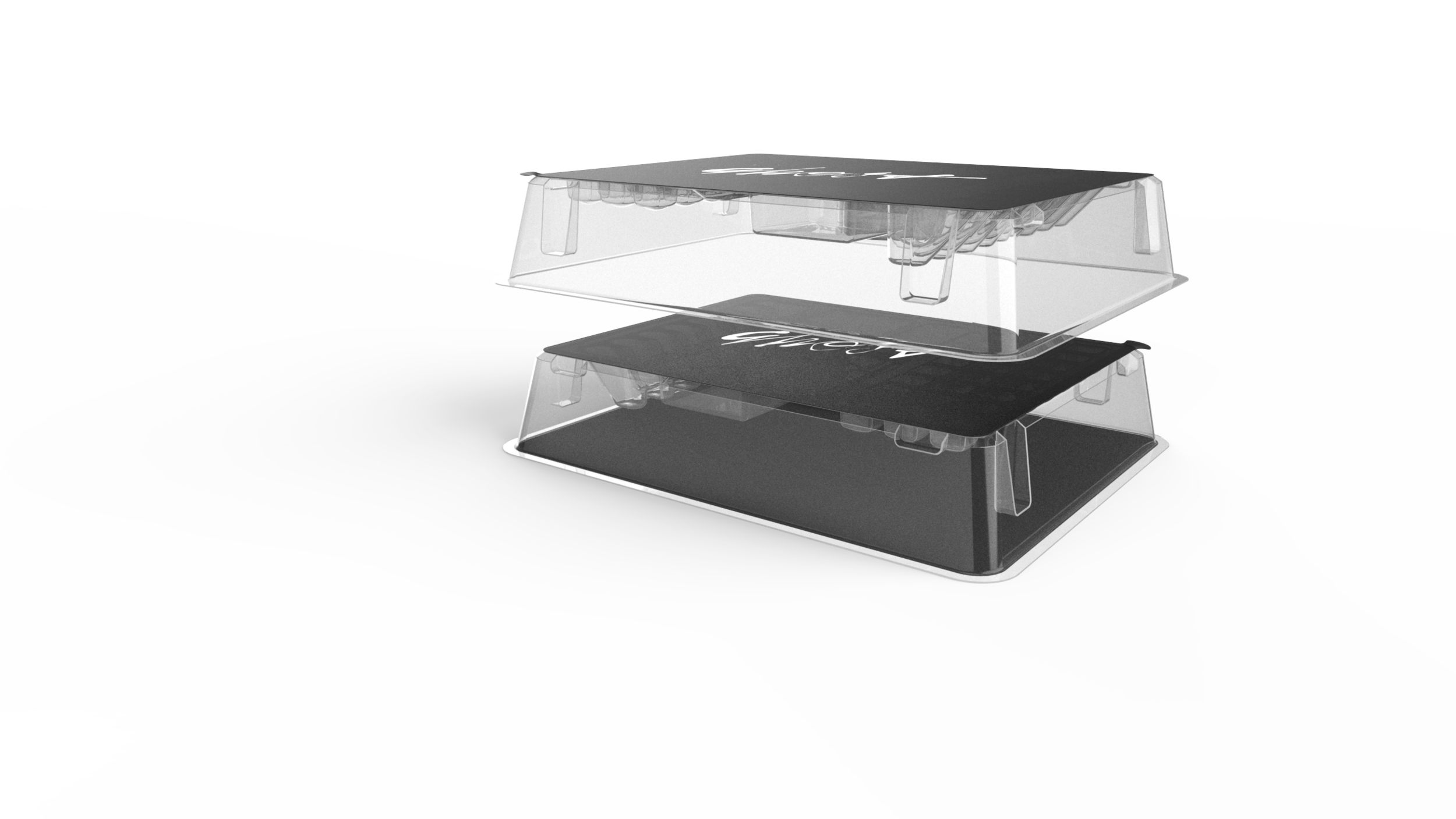

Though tattoo artists use many of the methods and supplies used for other medical procedures, most don’t have the training in aseptic technique that’s common in operating rooms and other health care settings. To improve both the safety and the user experience of all involved, the team strove to provide a tray that could facilitate aseptic technique.

This project leveraged the ethnographic experience the P&T team has in the sterile method. Our team has observed and documented dozens of surgical procedures in support of other projects in the surgical space. This experience proved vital to create a tattoo tray that promotes aseptic technique.

Logistics

Sterile supplies are commonly available from dozens of medical supply companies, but because none caters specifically to the needs of tattoo artists, no single source supplier carries all the items an artist requires for his/her work. Tattoo artists are forced to curate and purchase consumables from a large number of different supply companies and inventory these items on a product-by-product basis. This creates a logistical problem that can be distracting or even disruptive for many artists.

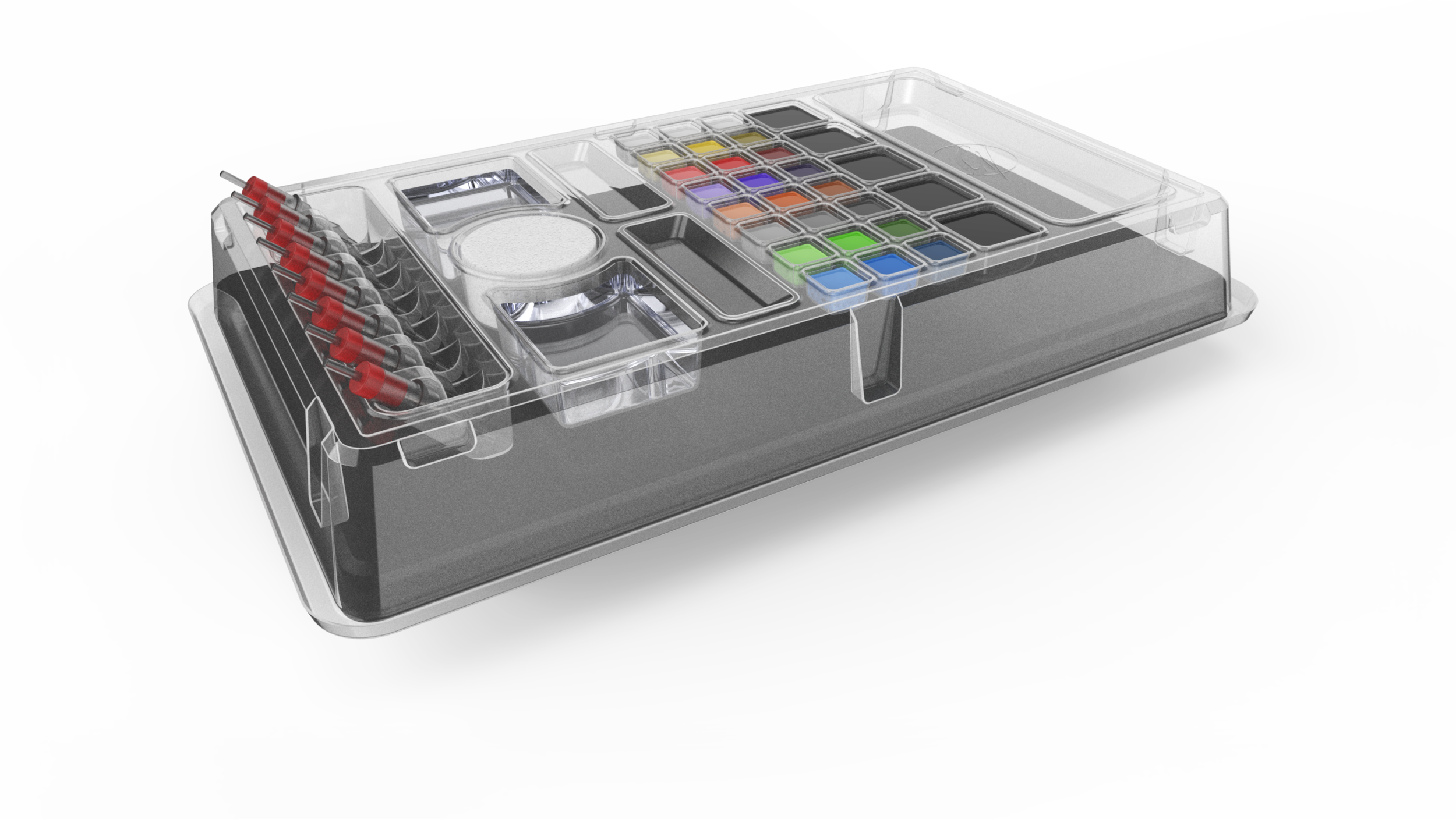

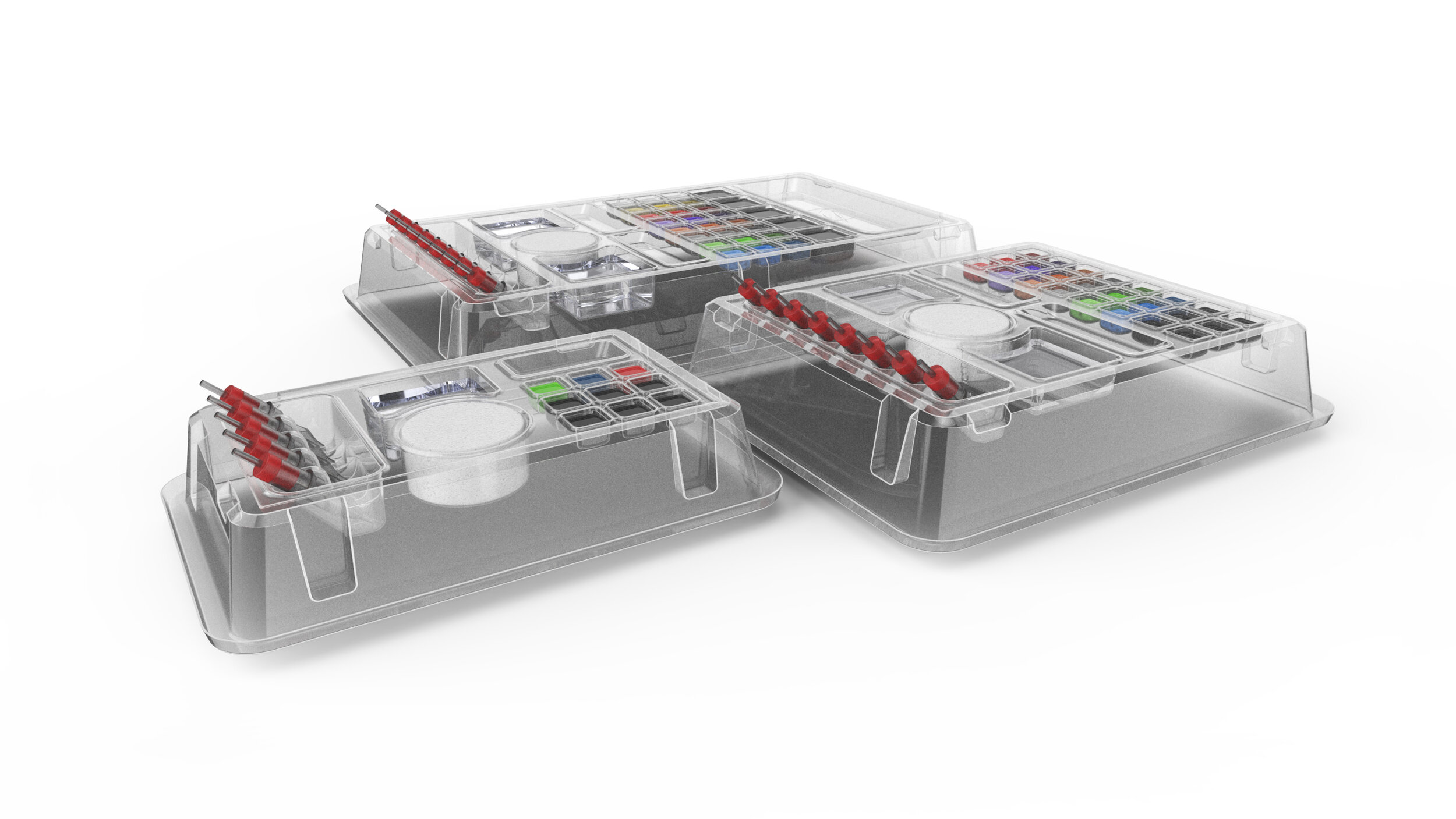

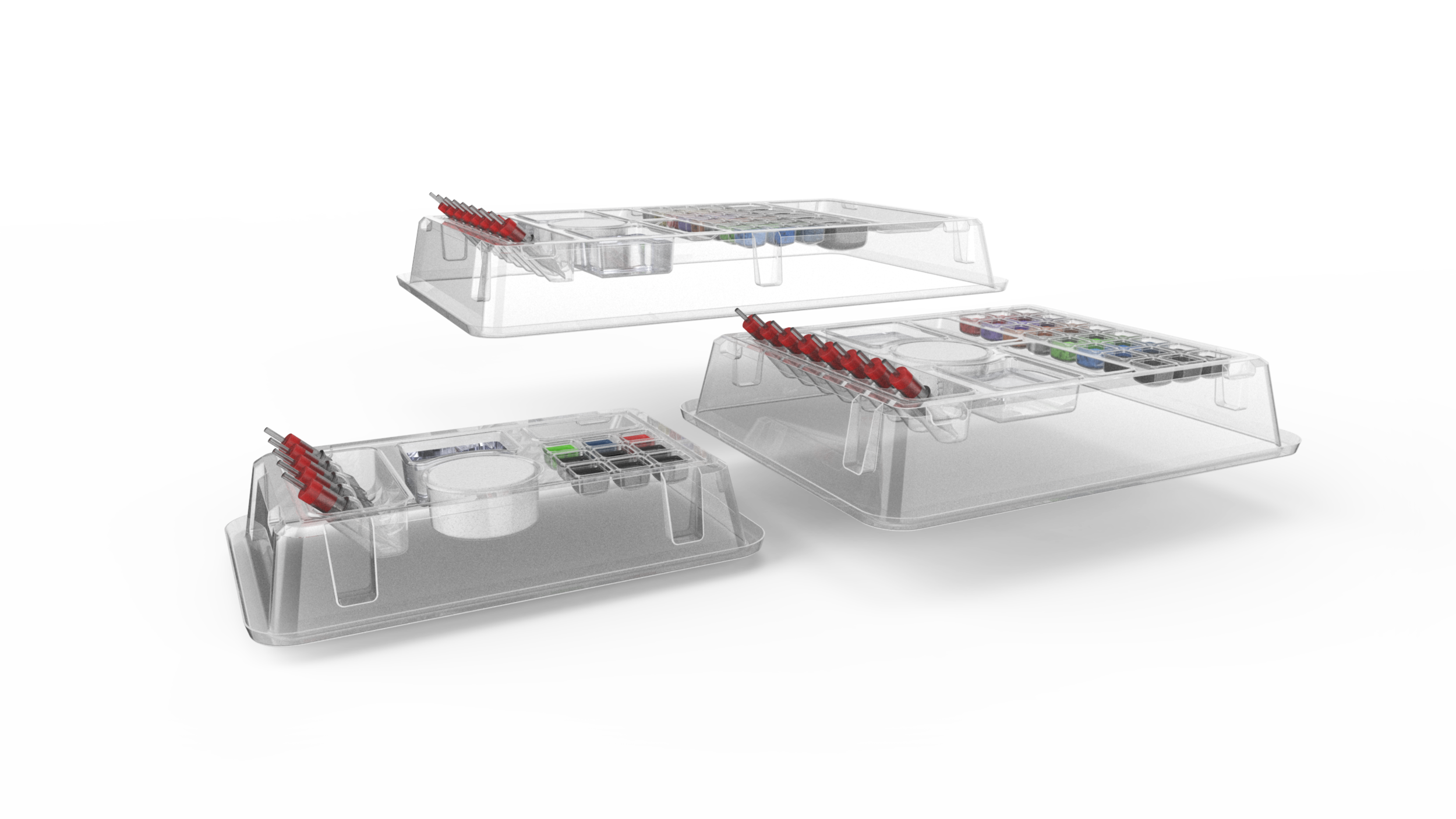

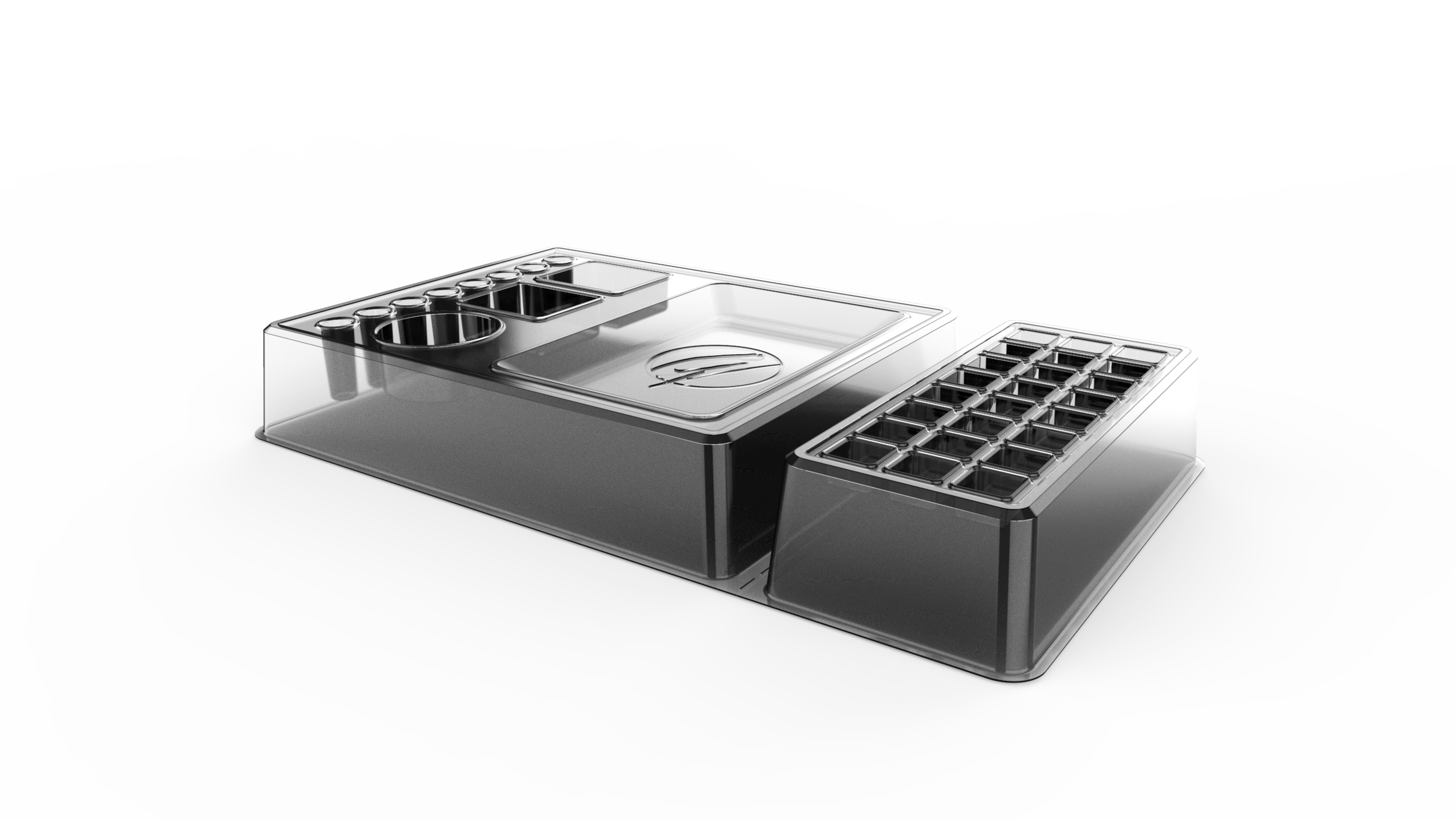

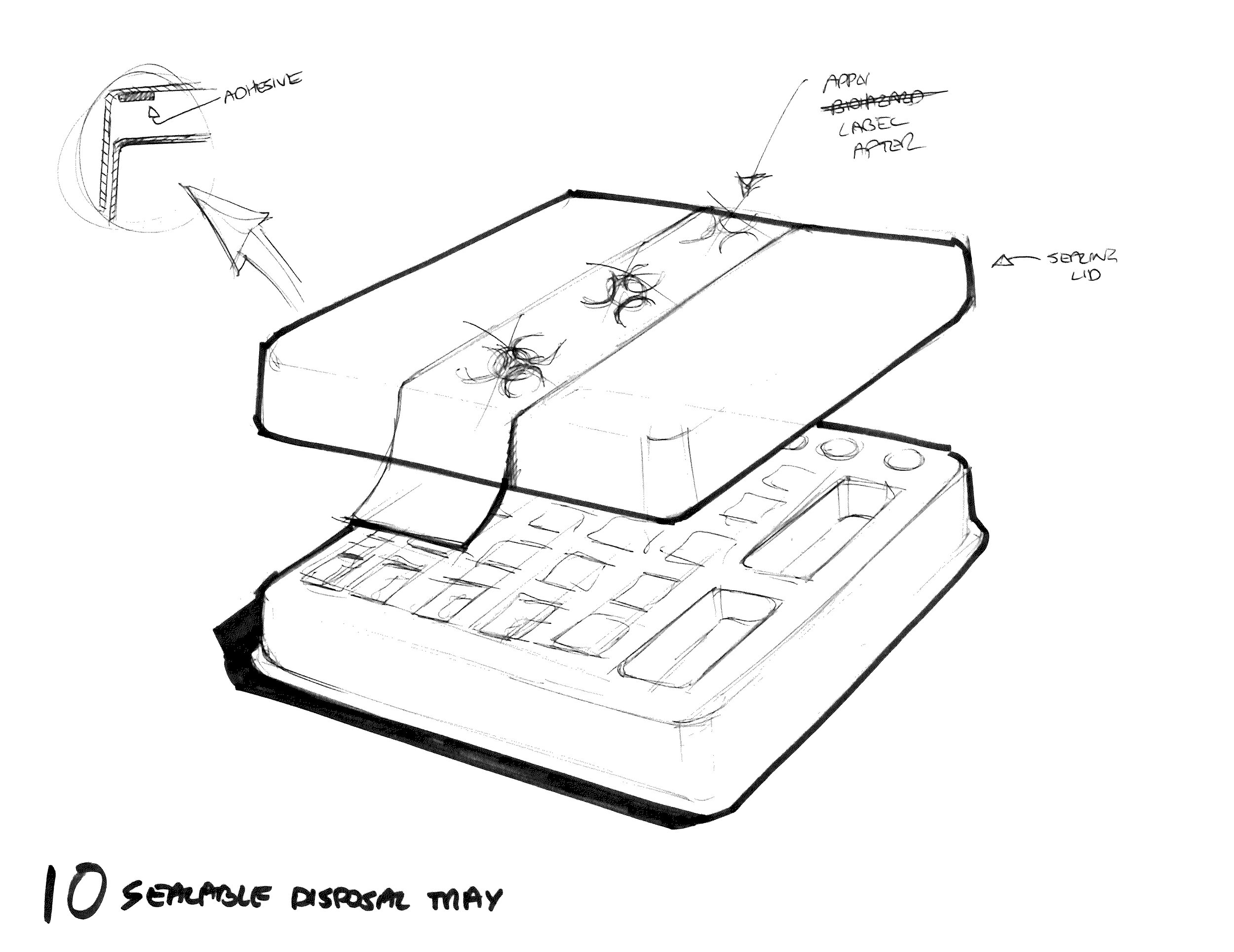

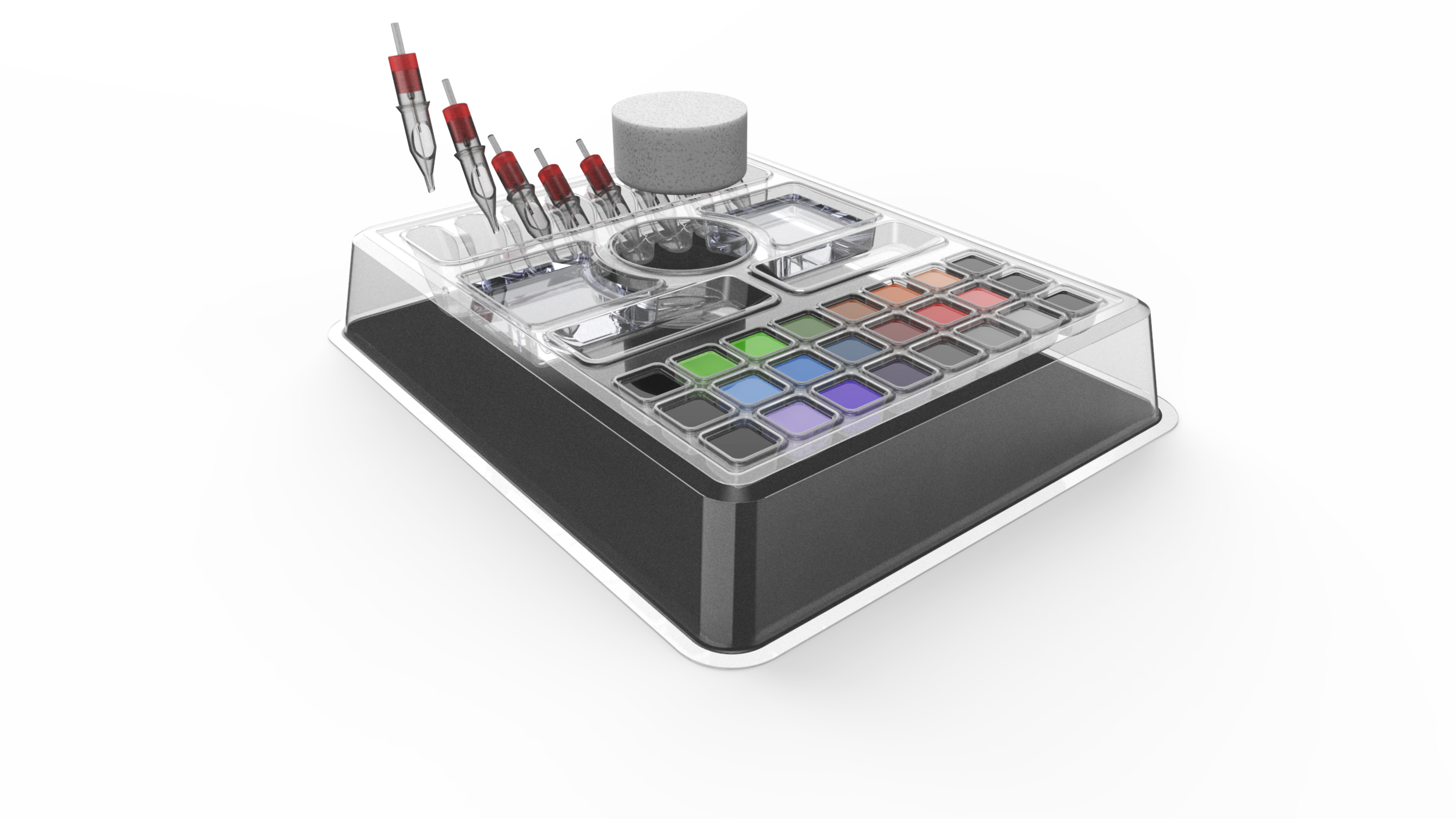

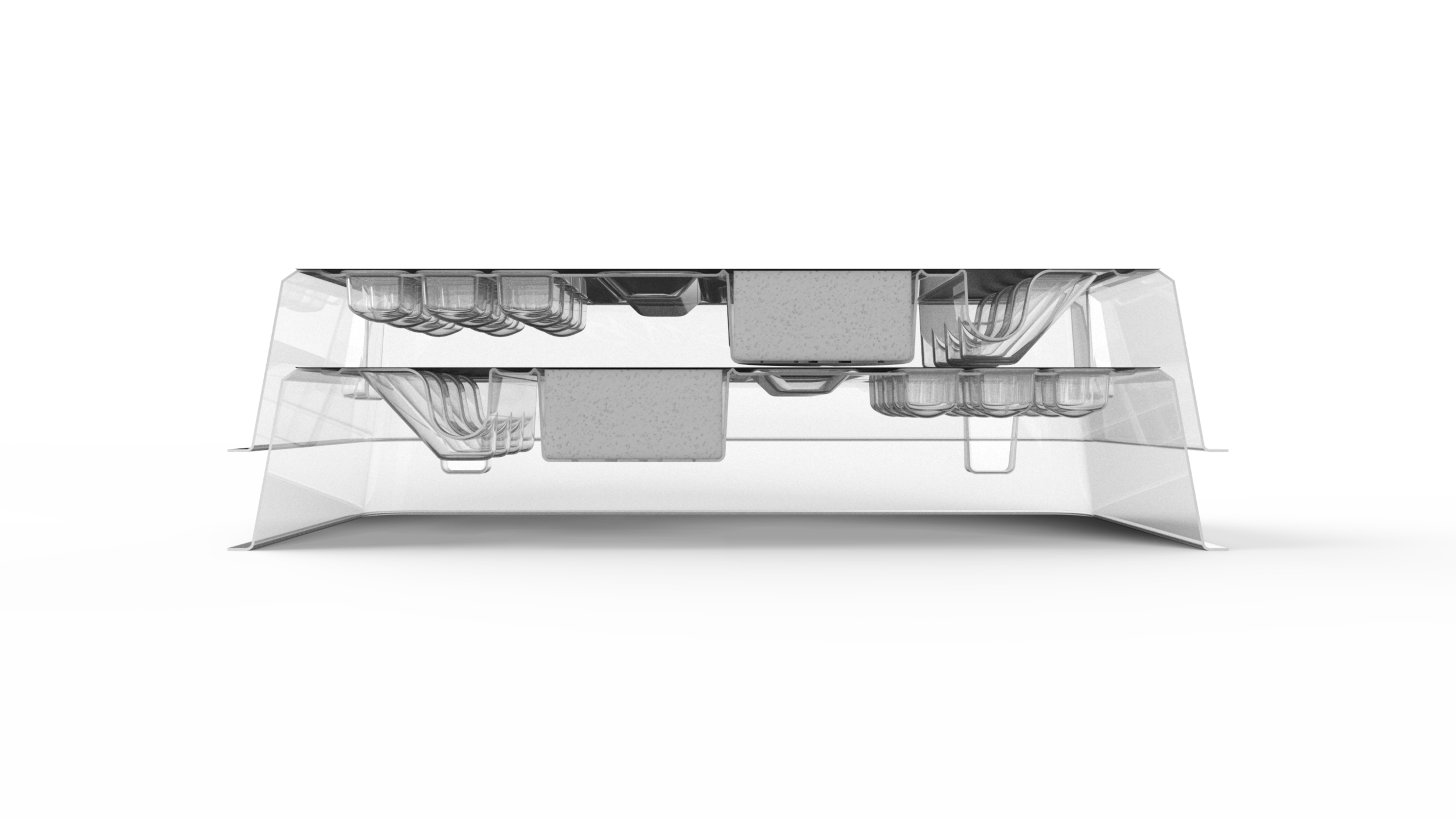

Founder Bryan Kilby’s logistical expertise led to the creation of a pre-packaged tray filled with all the supplies needed for a single tattoo client.

Collaborative Product Development

Our experience has shown that the most effective way to get a new product invention to market is to marry the firsthand knowledge of an expert user to a product development process based on collaboration. By designing the product collaboratively — rather than behind closed doors as most agencies do — we are able to balance the technical needs of the product (cost, manufacturing, et al.) against the needs of the user in real time. This means a live give-and-take between product requirements, driven by the expertise of the client, who is both the owner of his/her business and a target customer. This process requires trust and humility from both parties, but the results are invariably fast and effective.

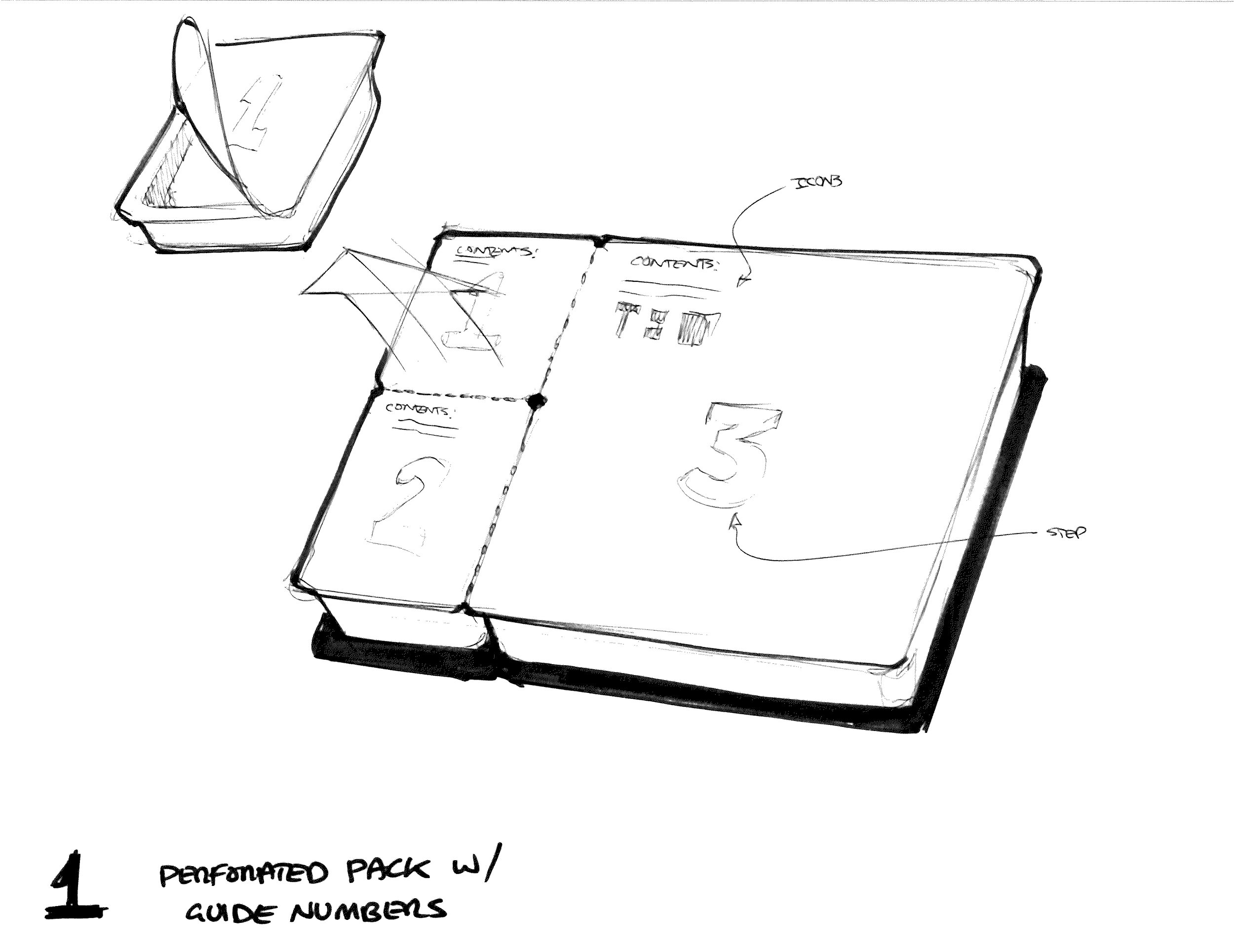

Ideation started with a discussion of a tattoo artist’s tools and the context and process in which they’re used.

User-Driven Design

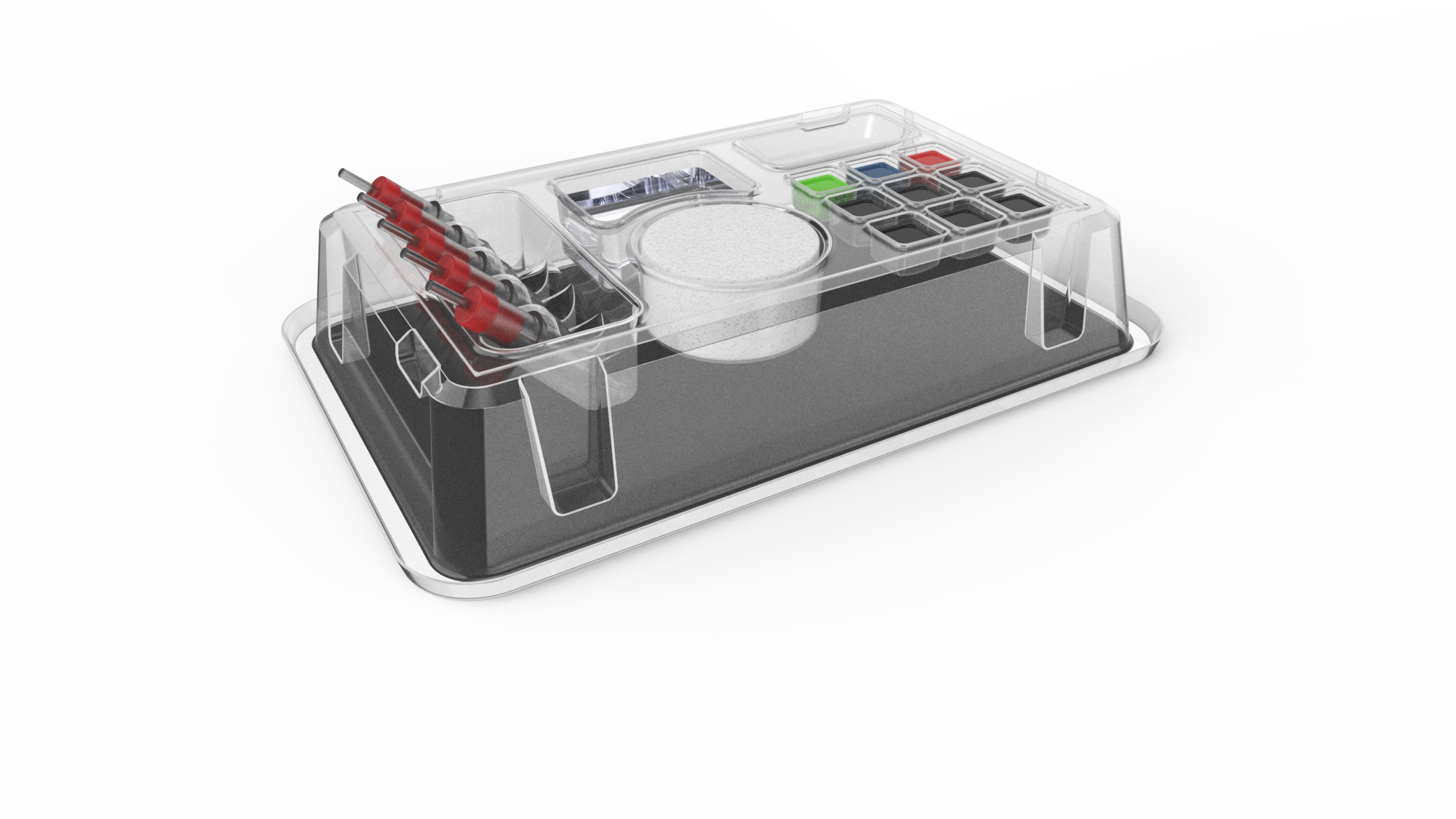

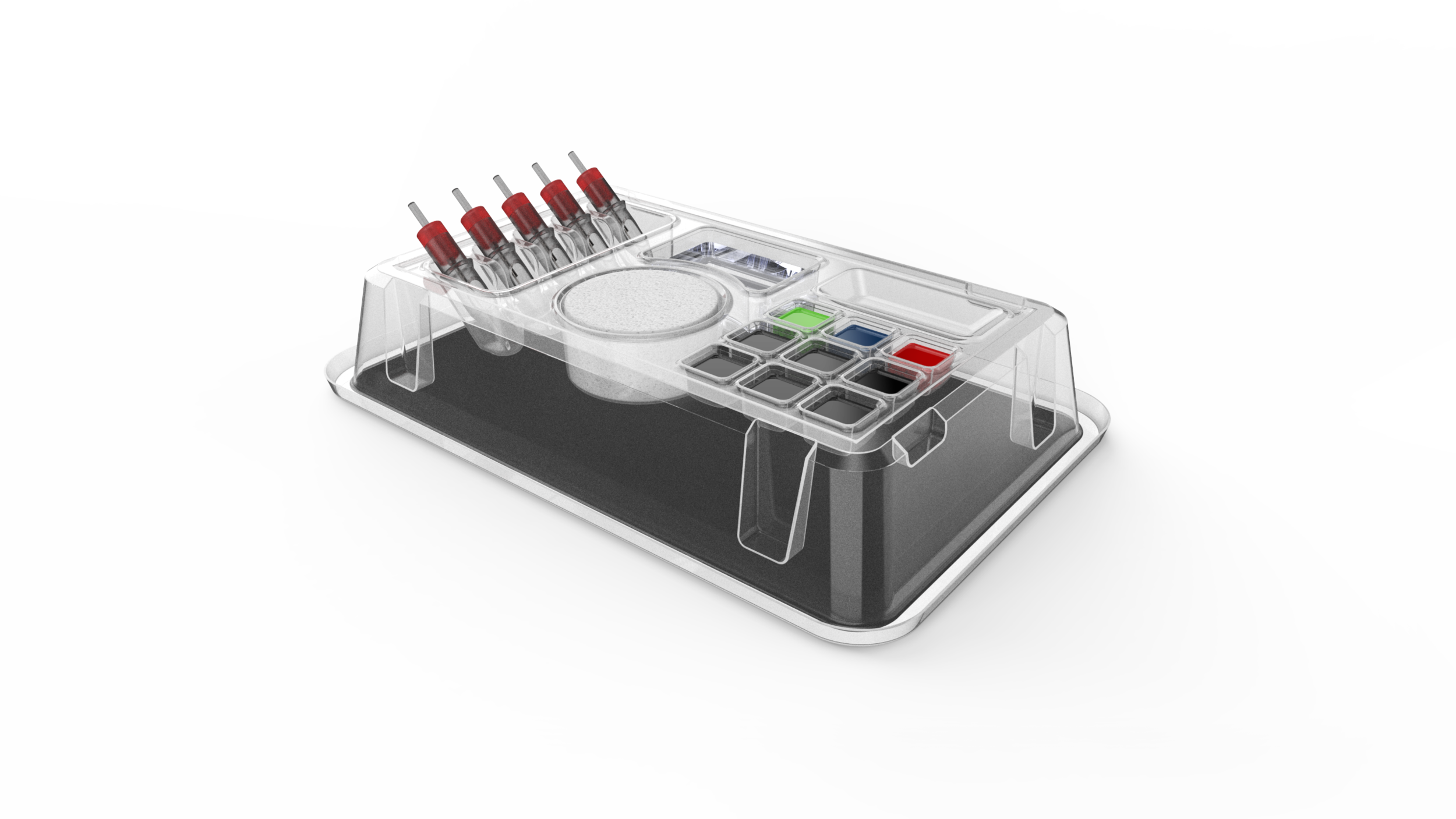

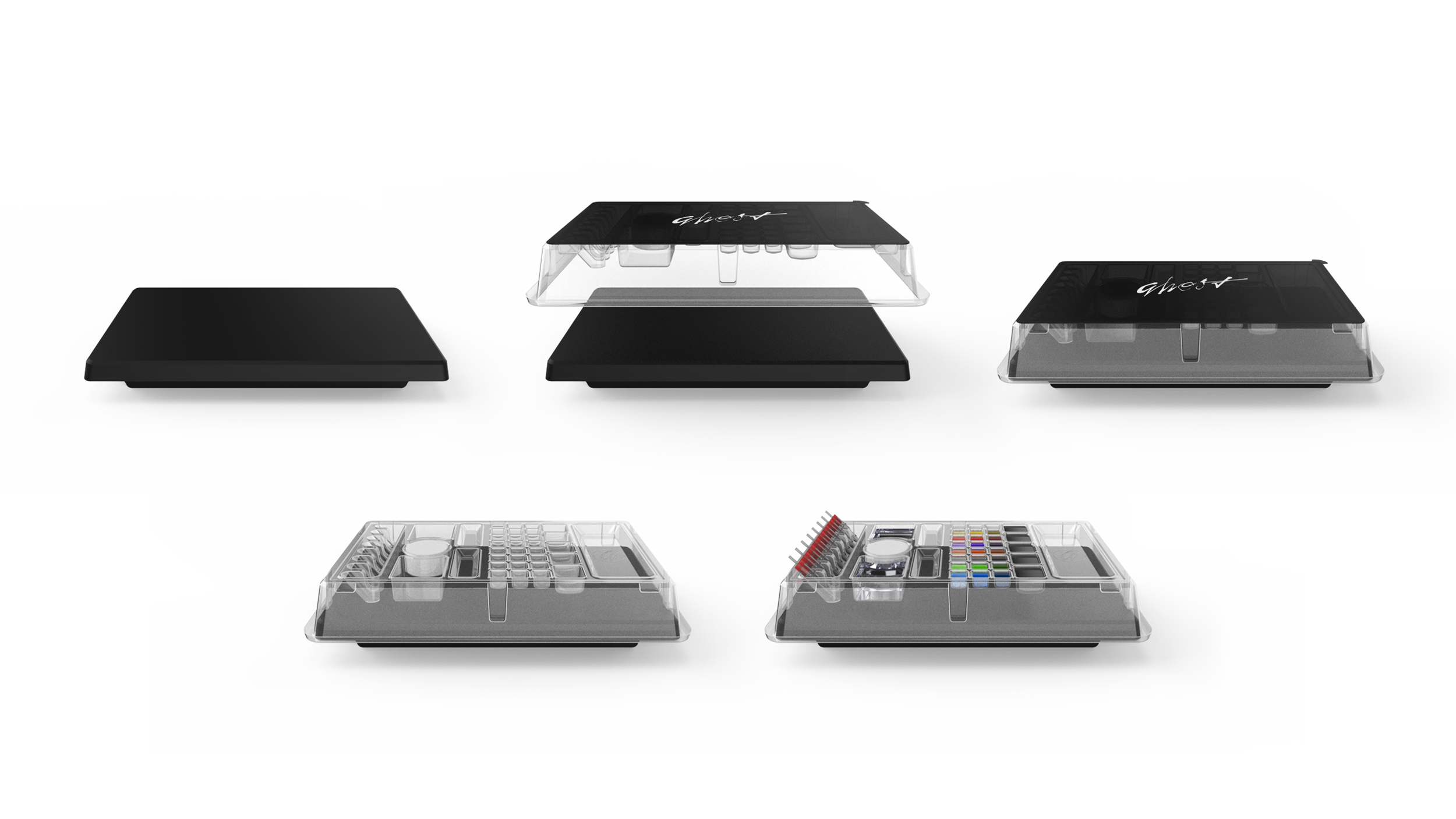

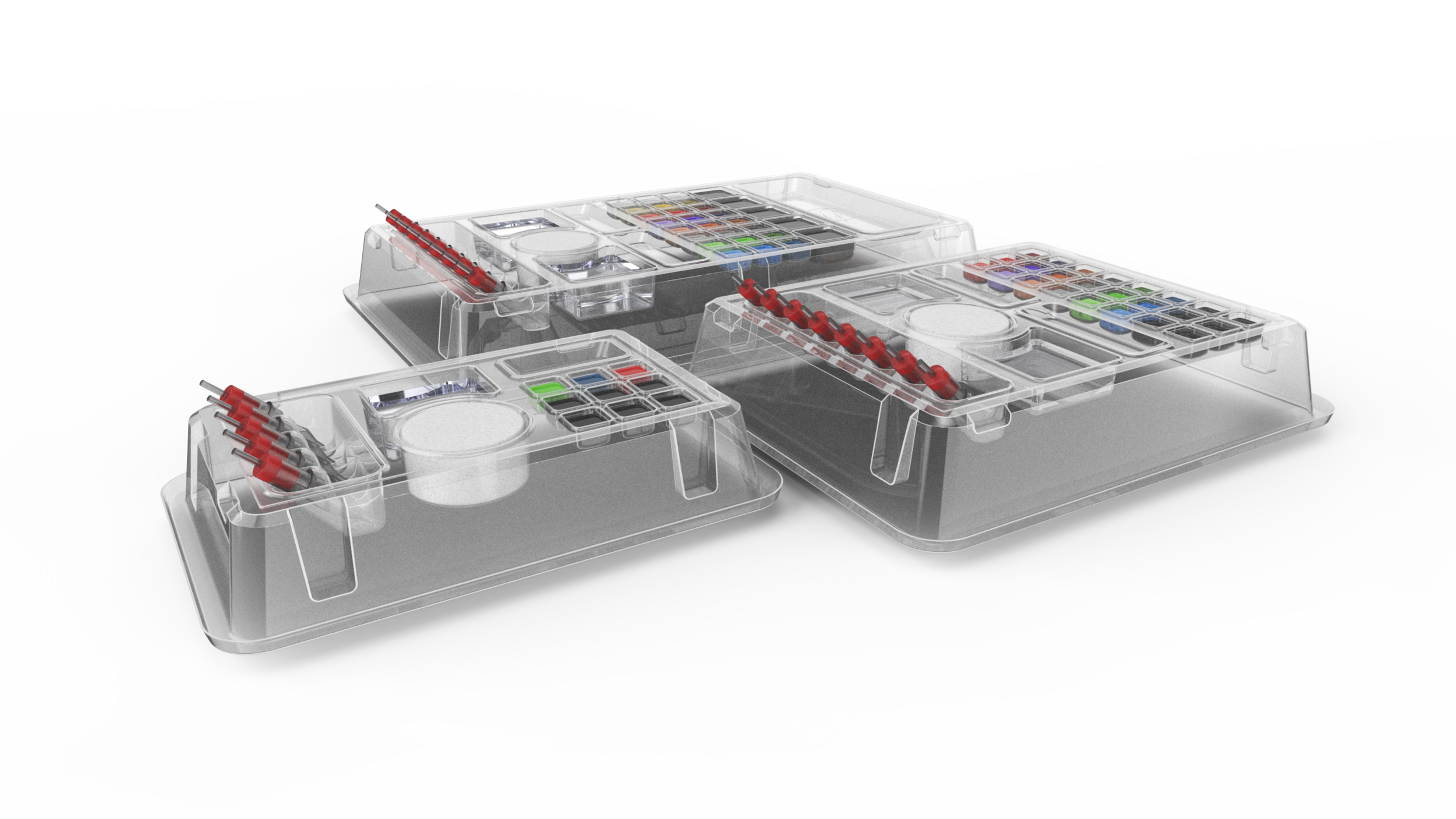

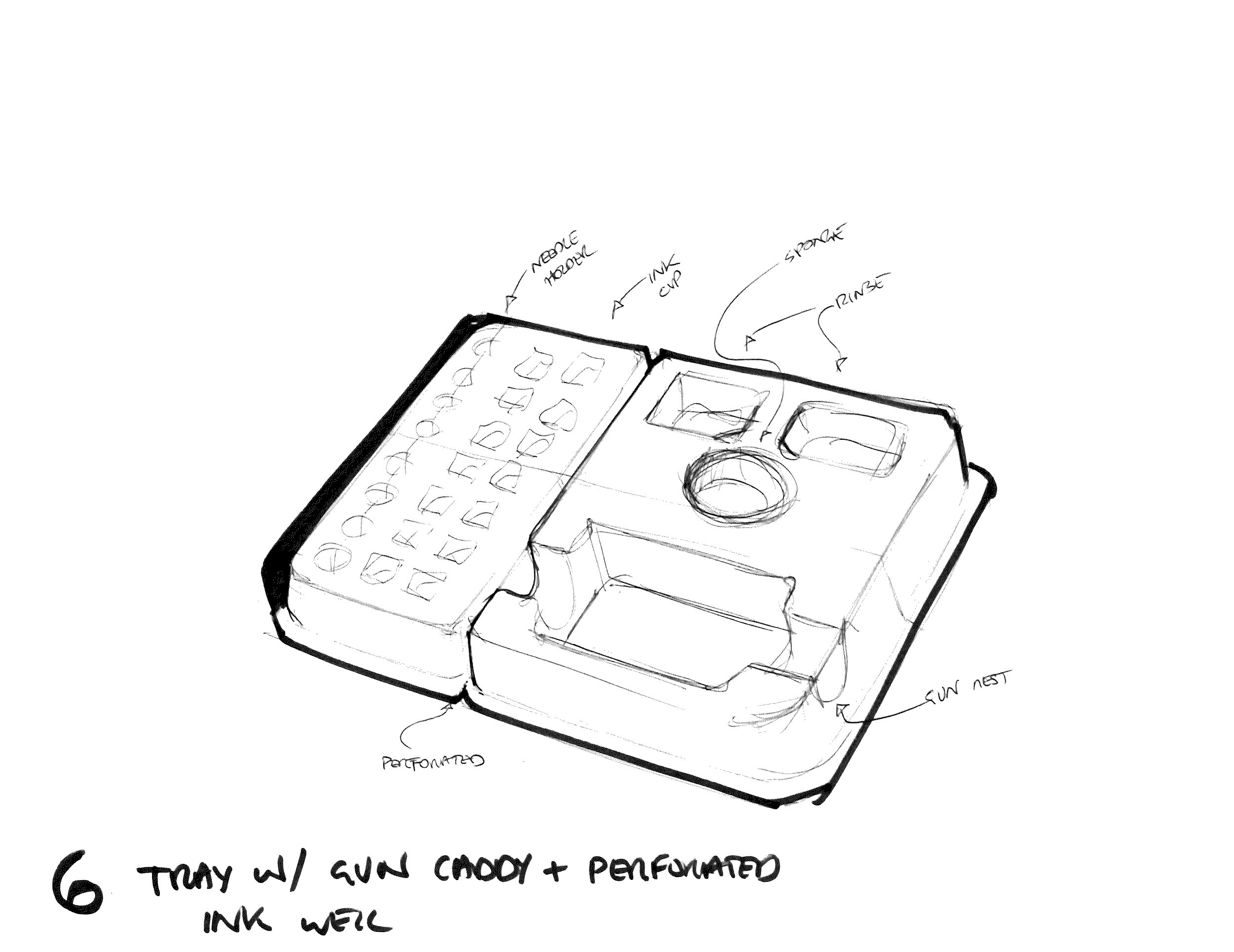

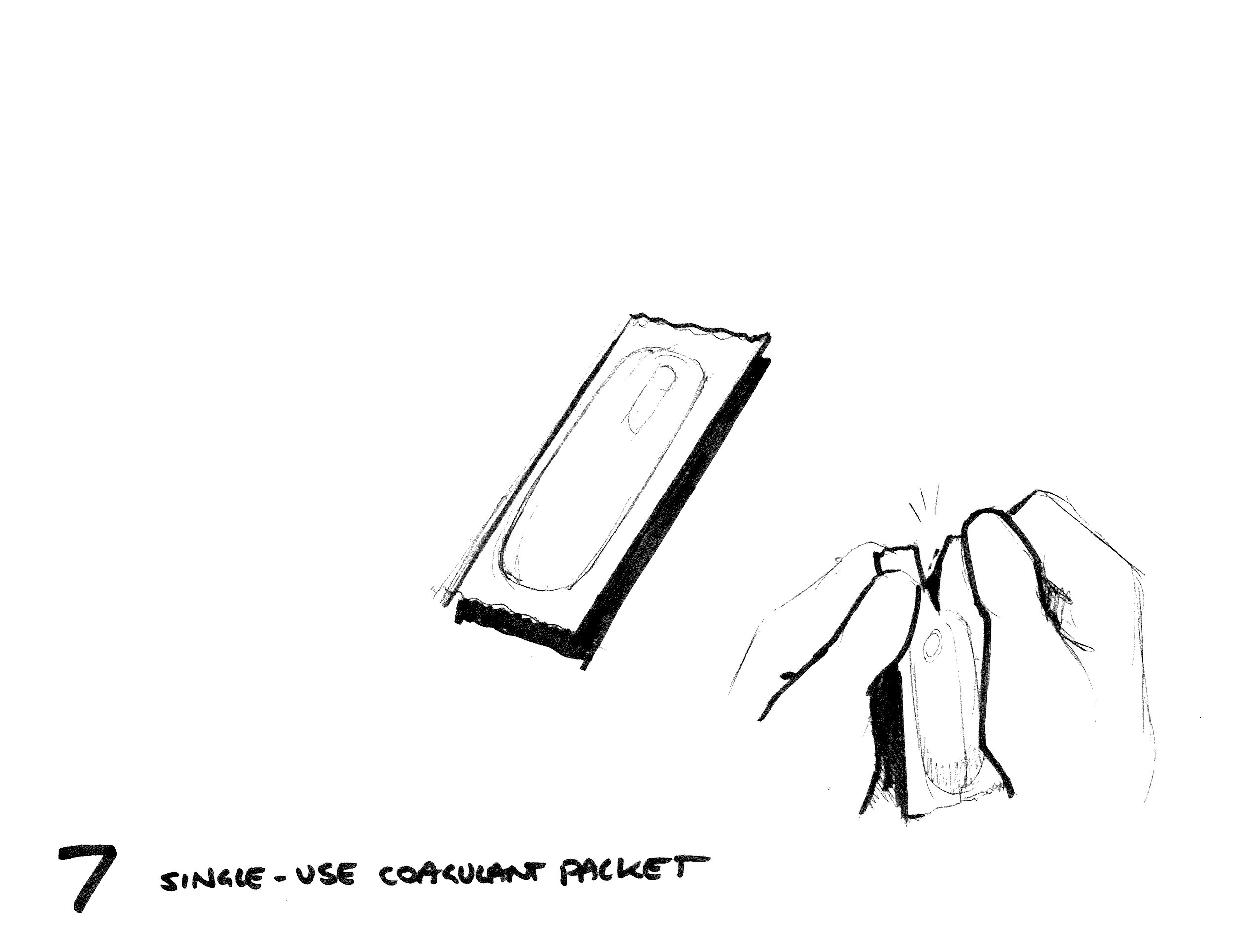

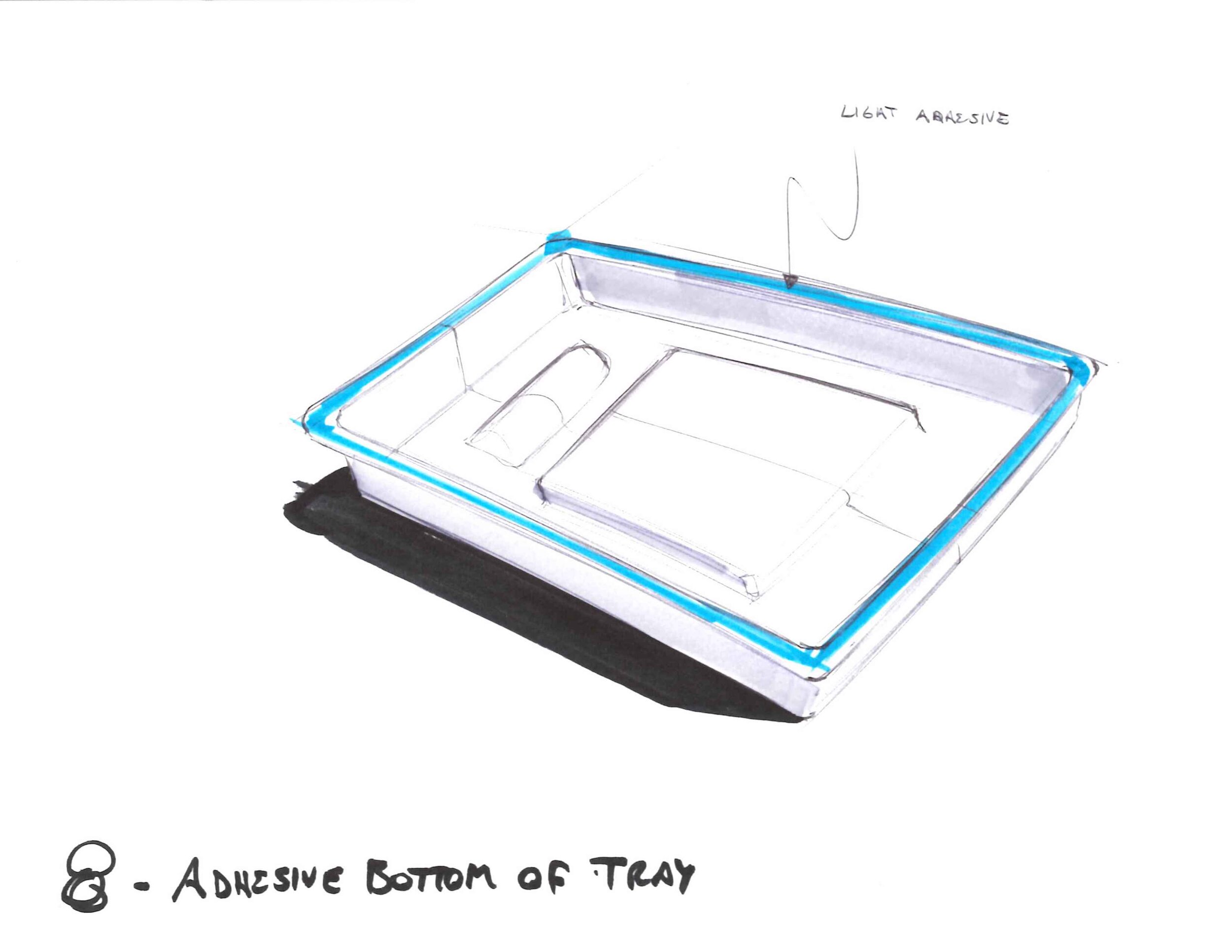

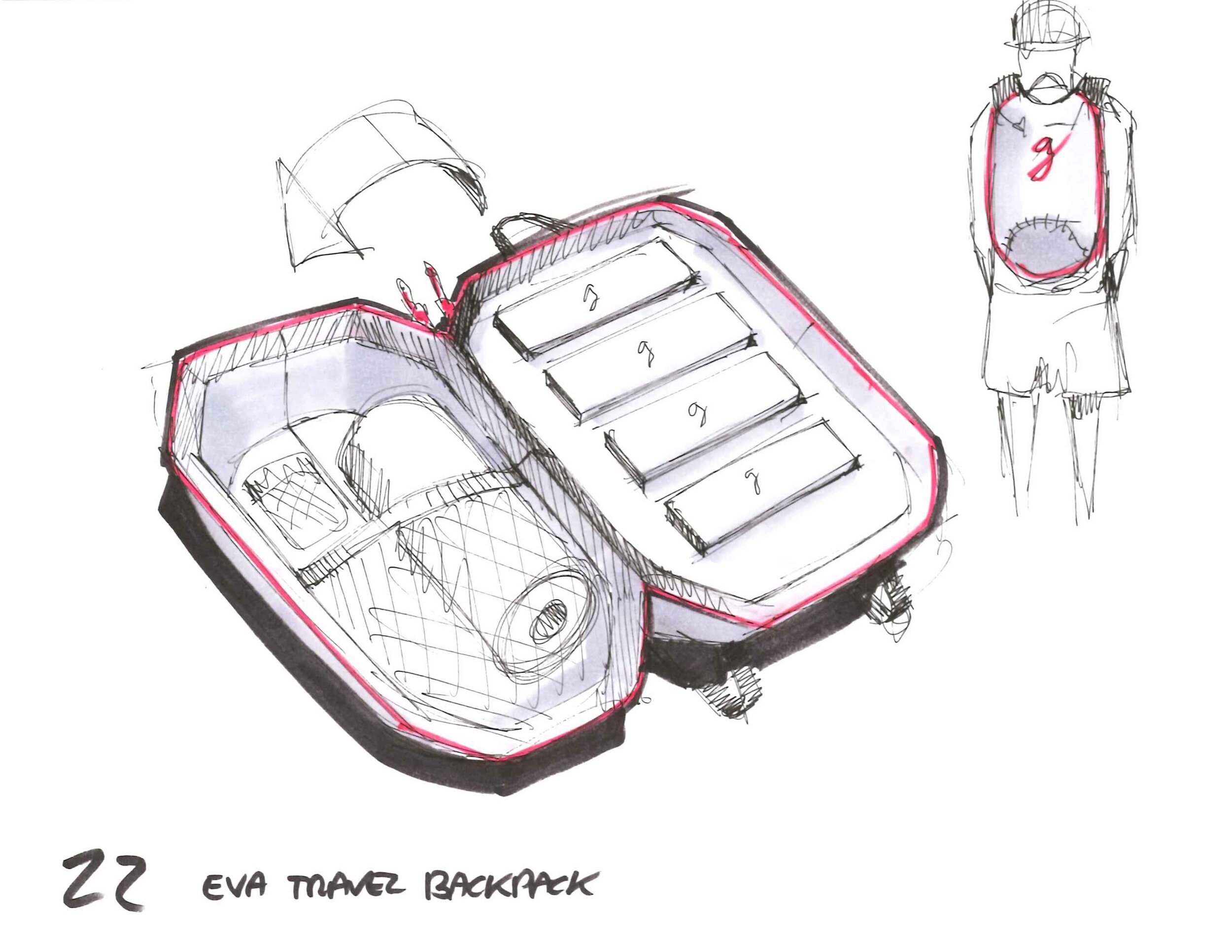

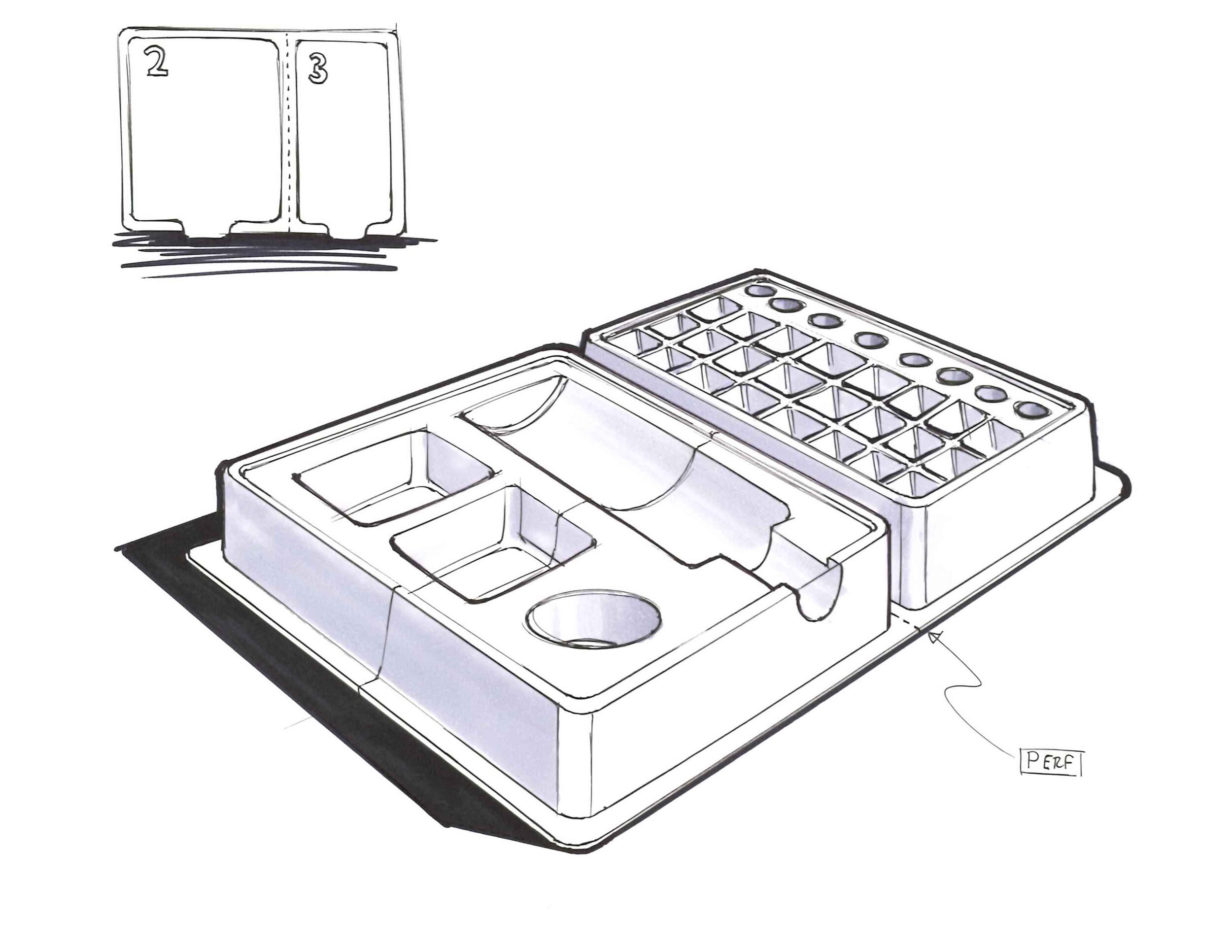

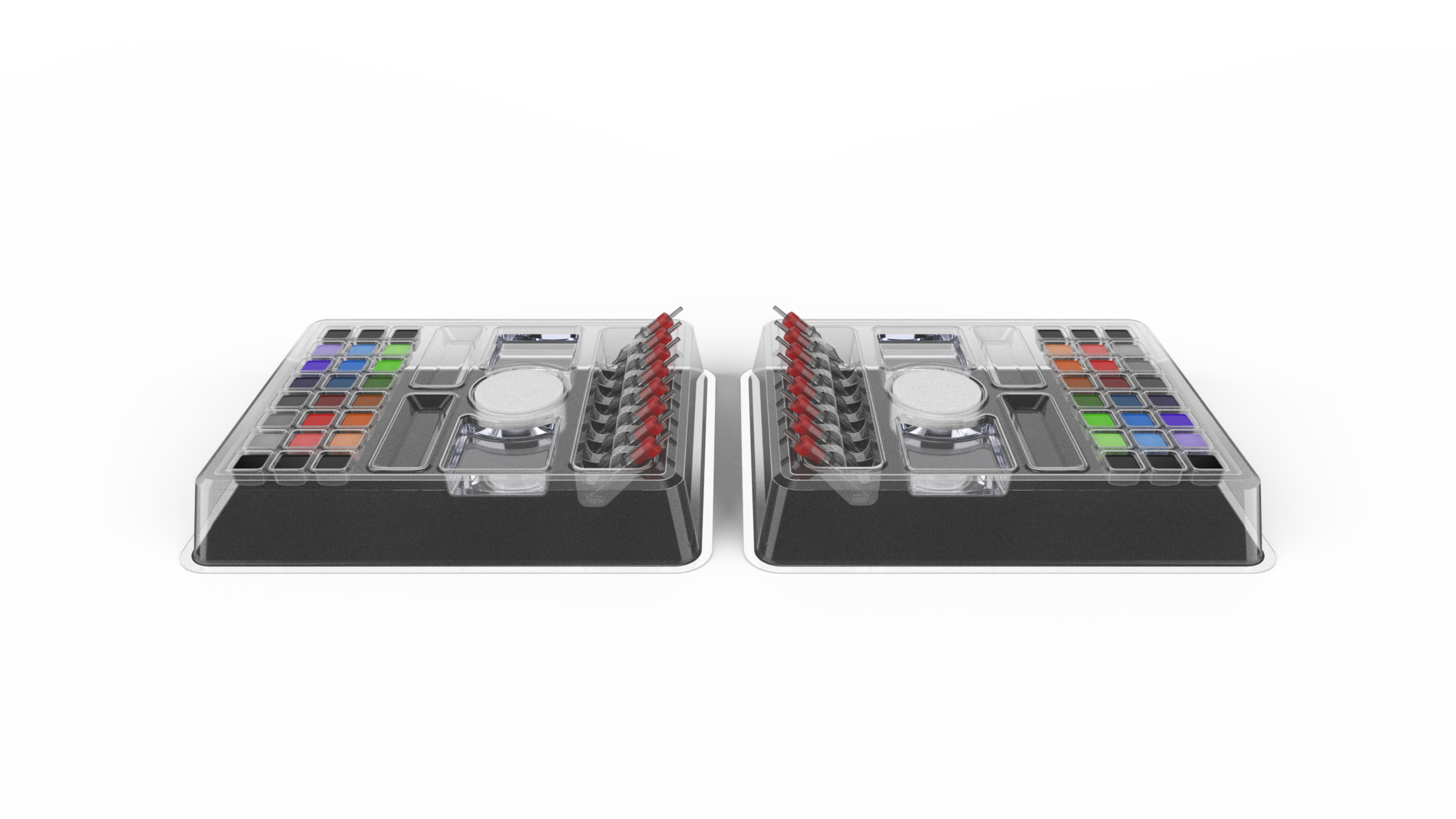

The design of these trays was driven by the knowledge of the Ghost team, which included deep insights about the medical supply industry and the user needs of the professional tattoo artist. The project began with an exploration of the user experience of a professional tattoo artist and an evaluation of the contents the kit must include. What followed was a blitzkrieg design and product development program that unfolded in a matter of days, not months.

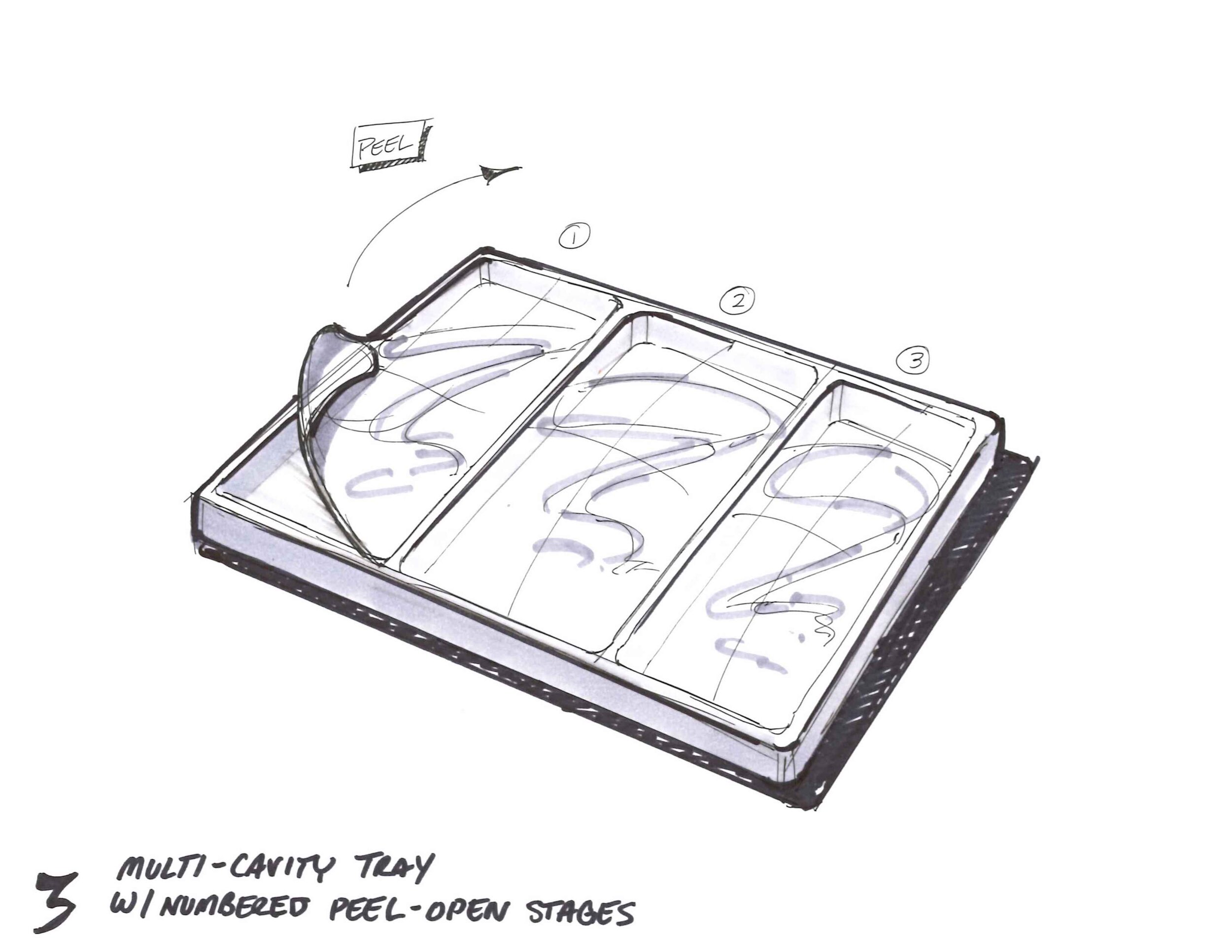

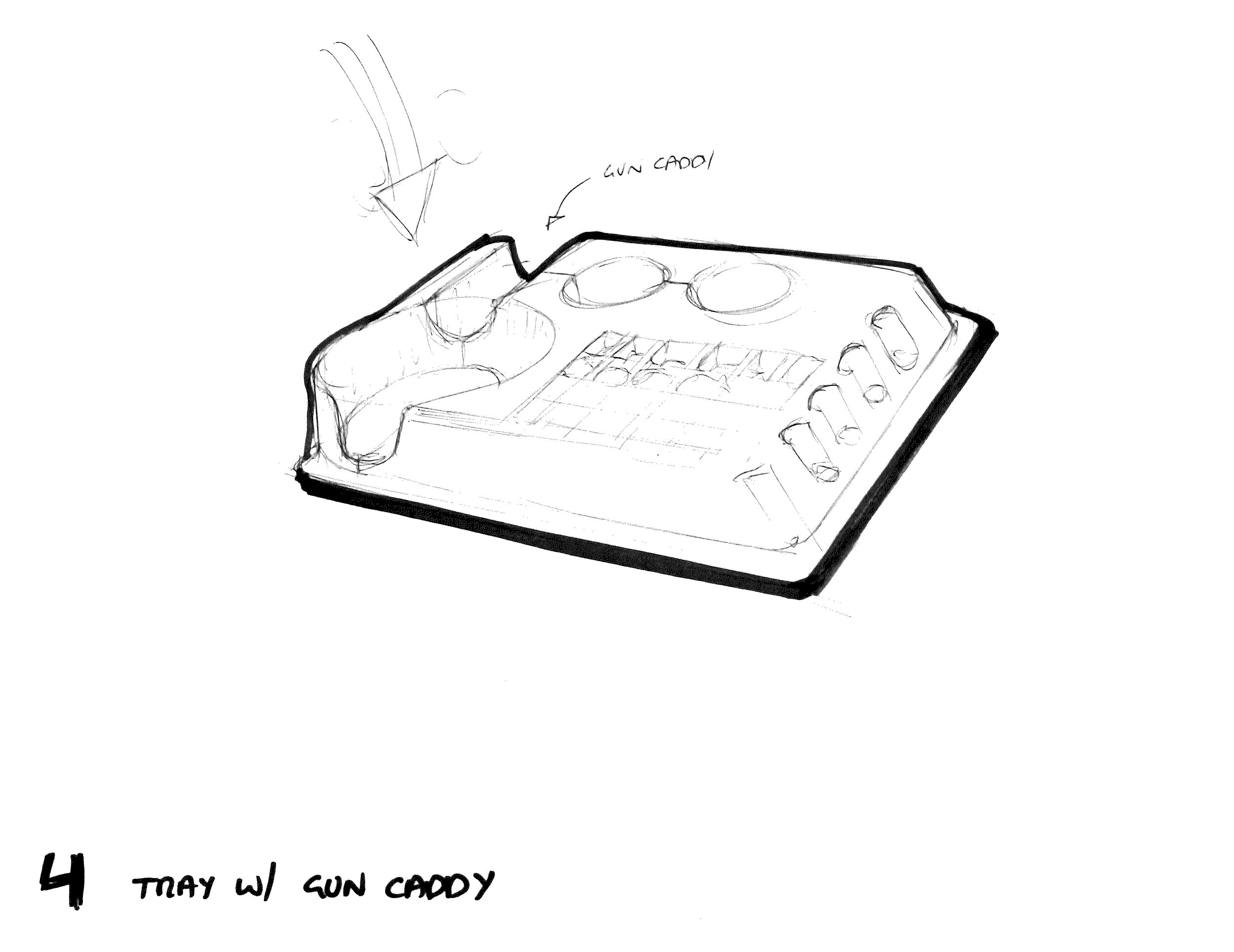

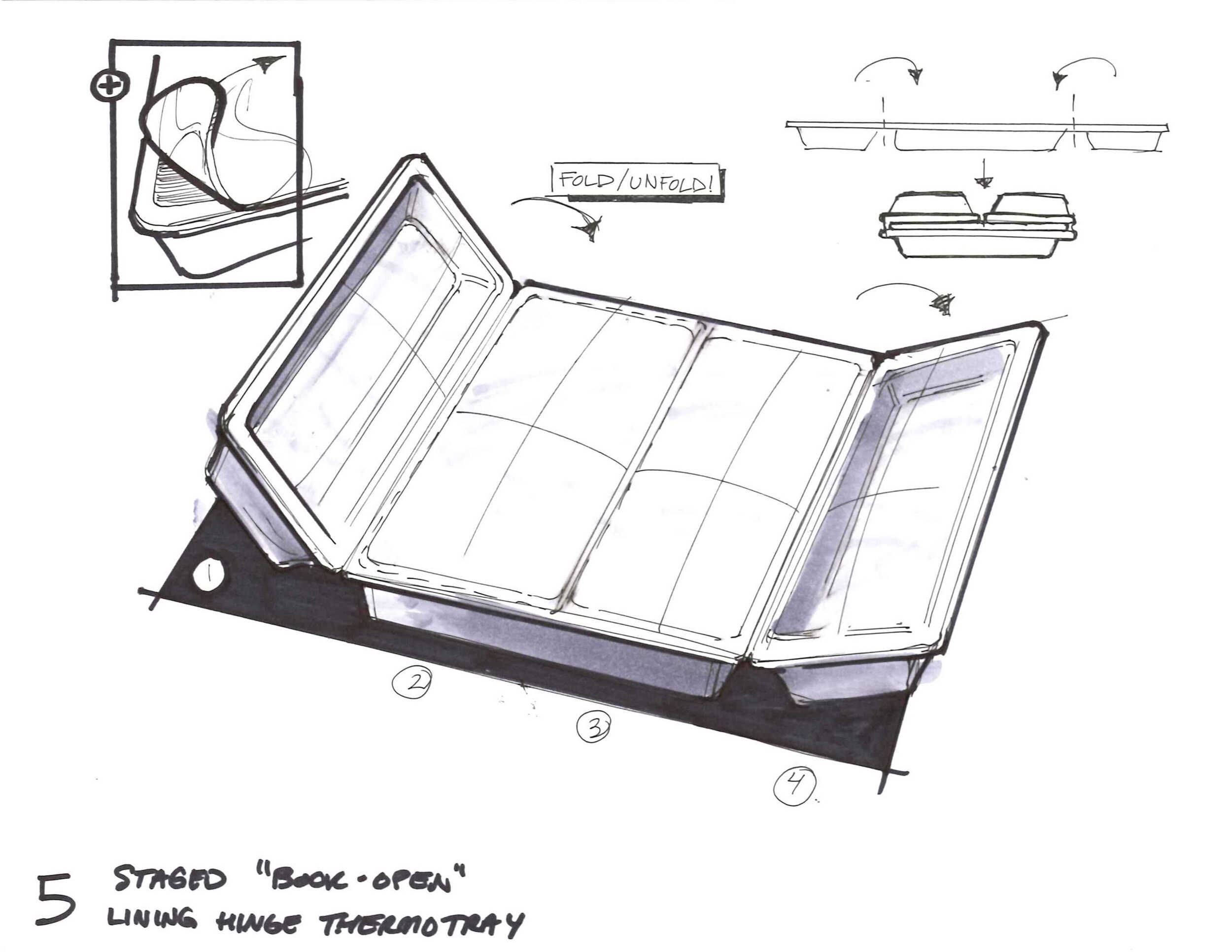

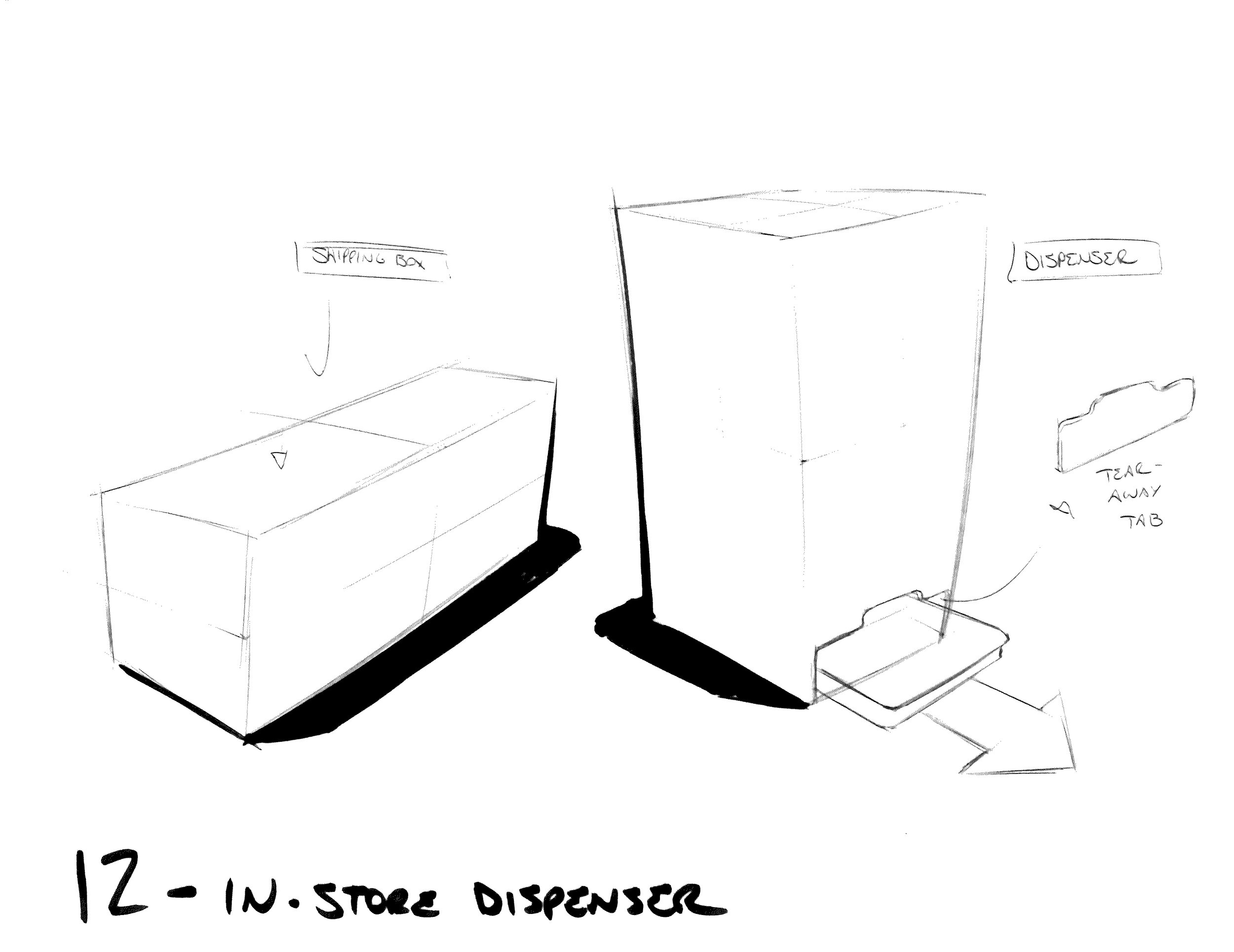

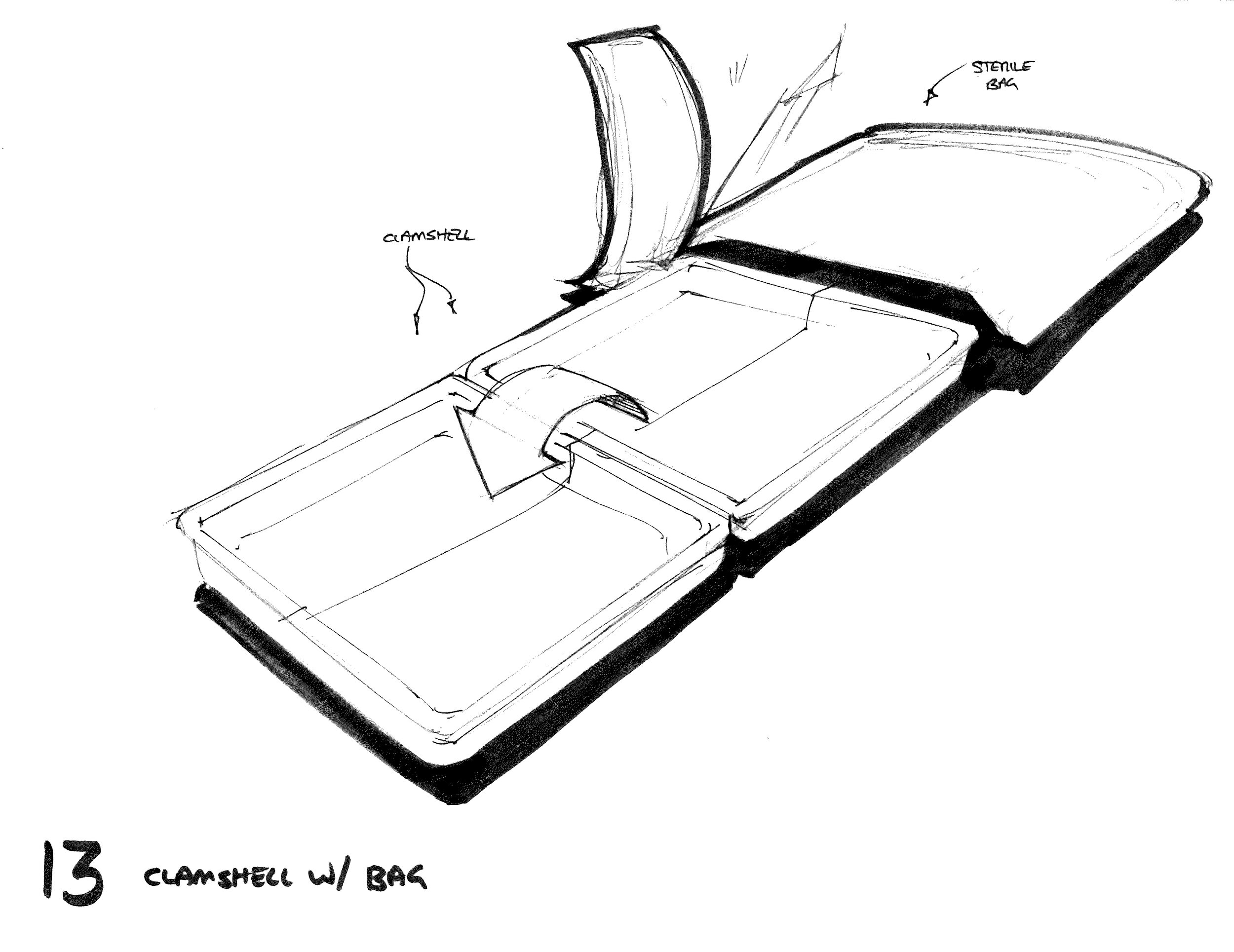

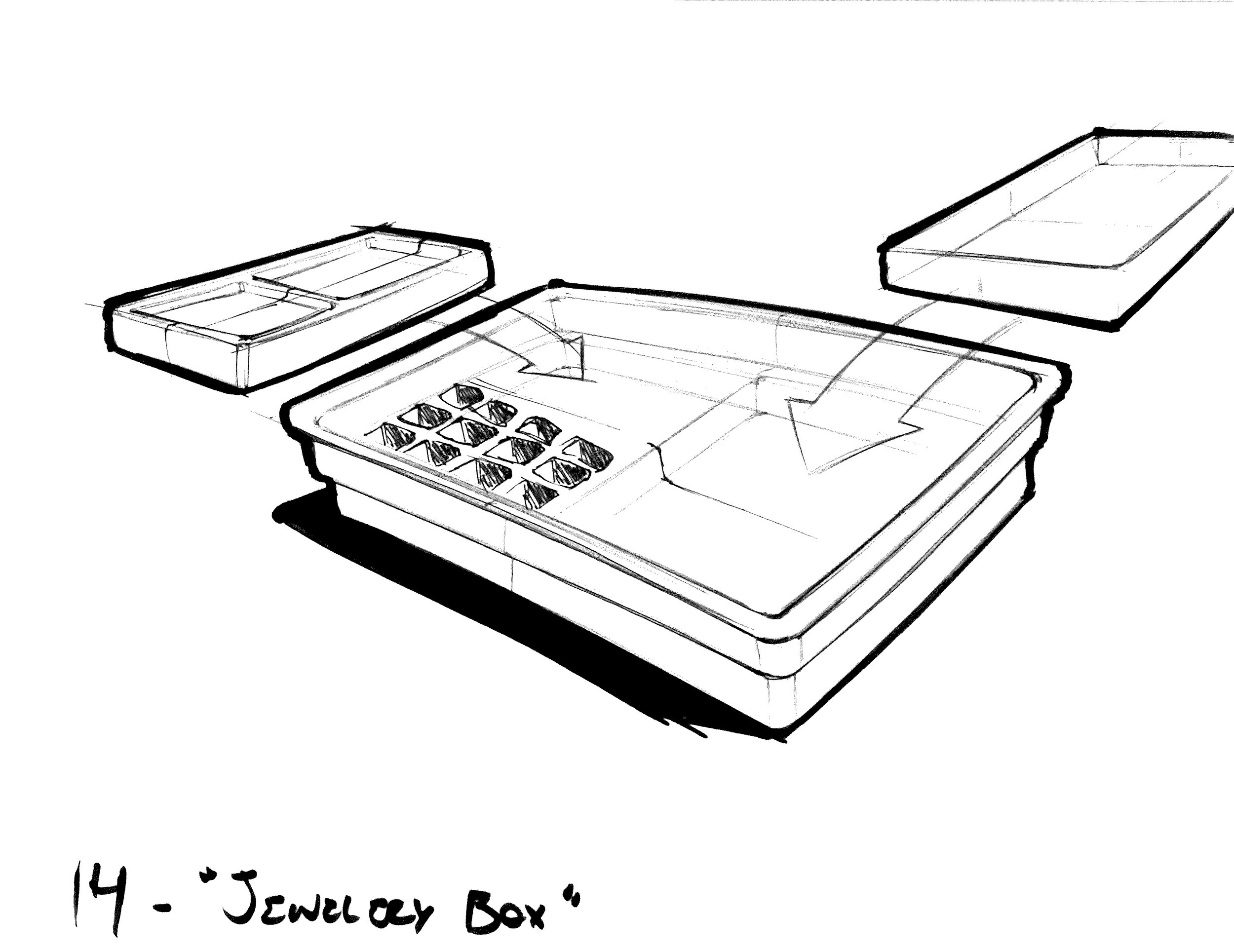

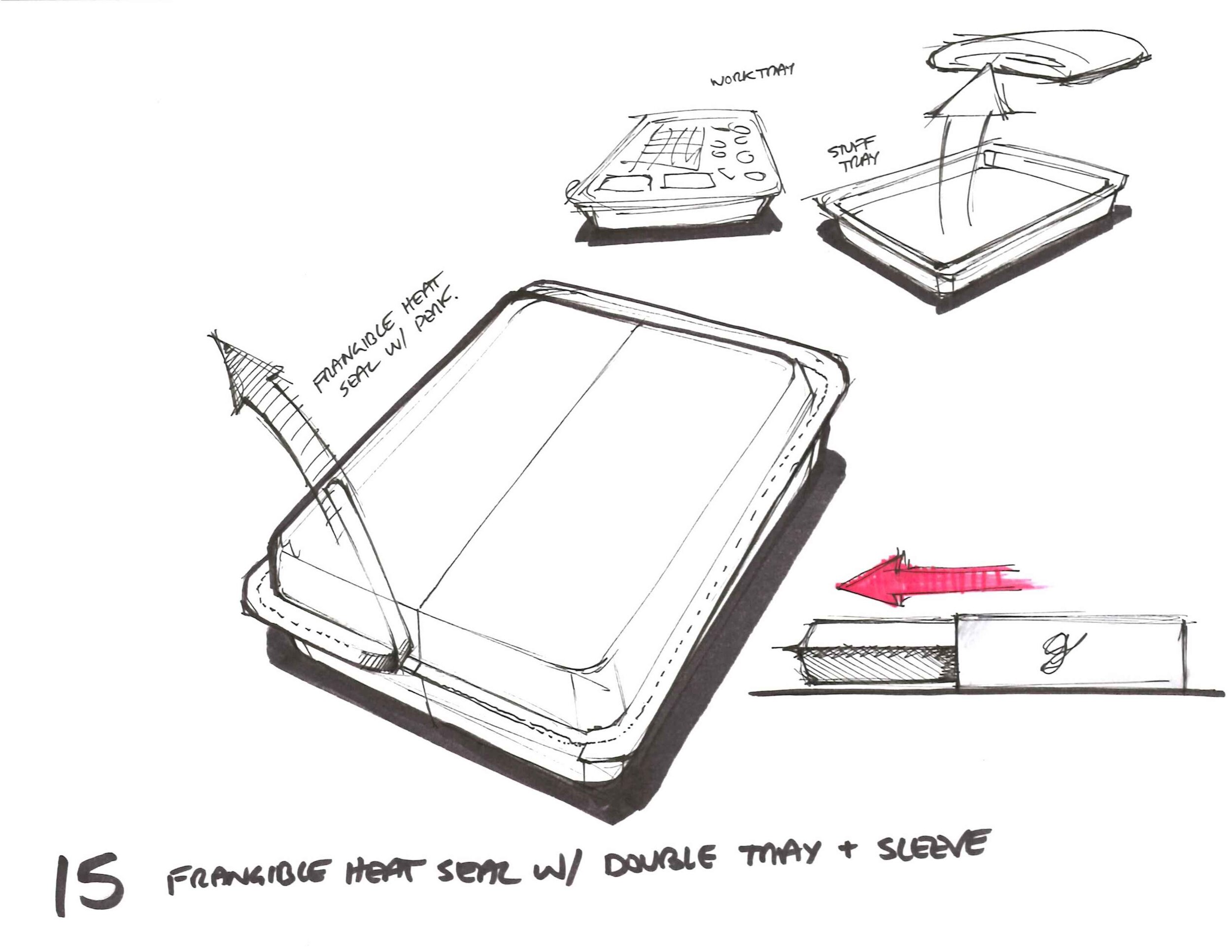

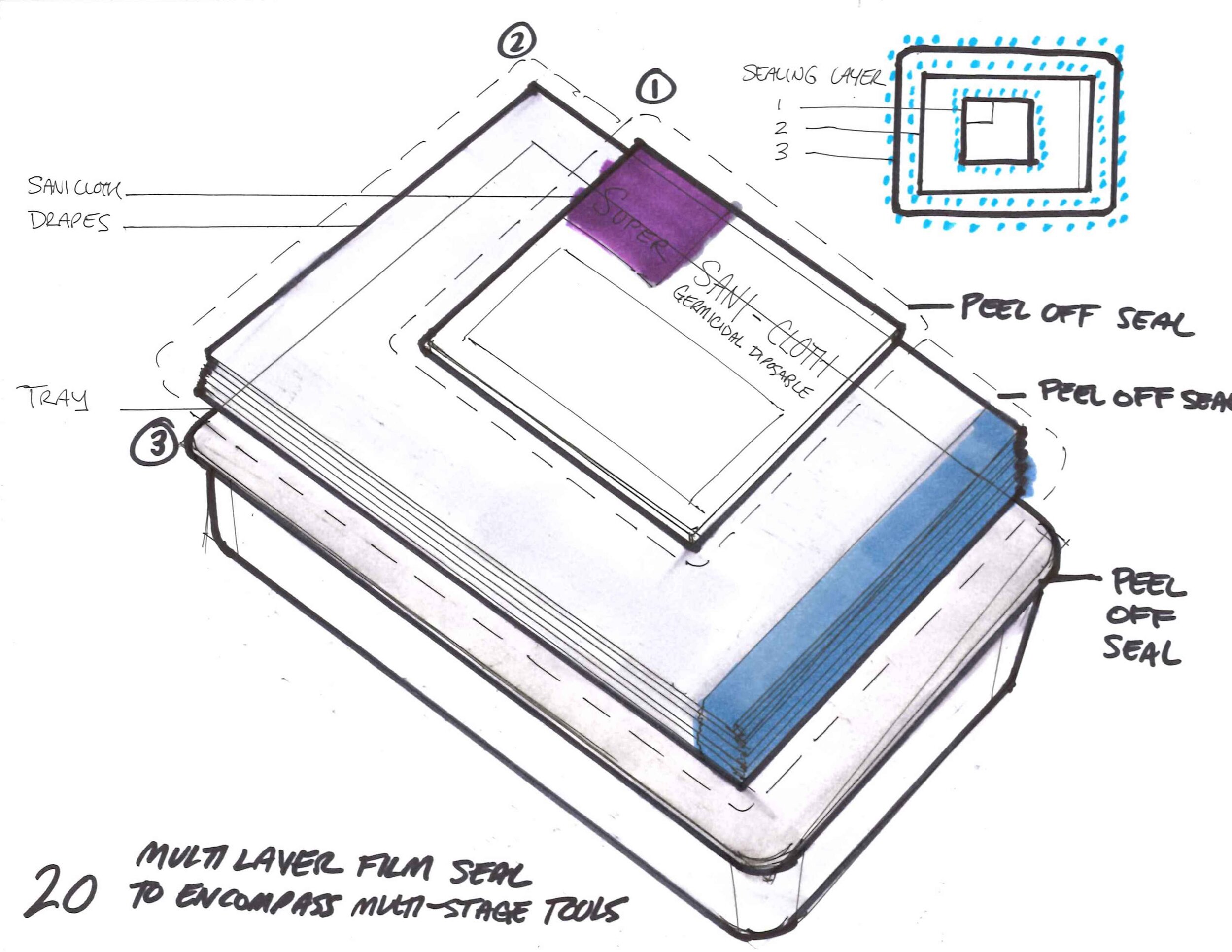

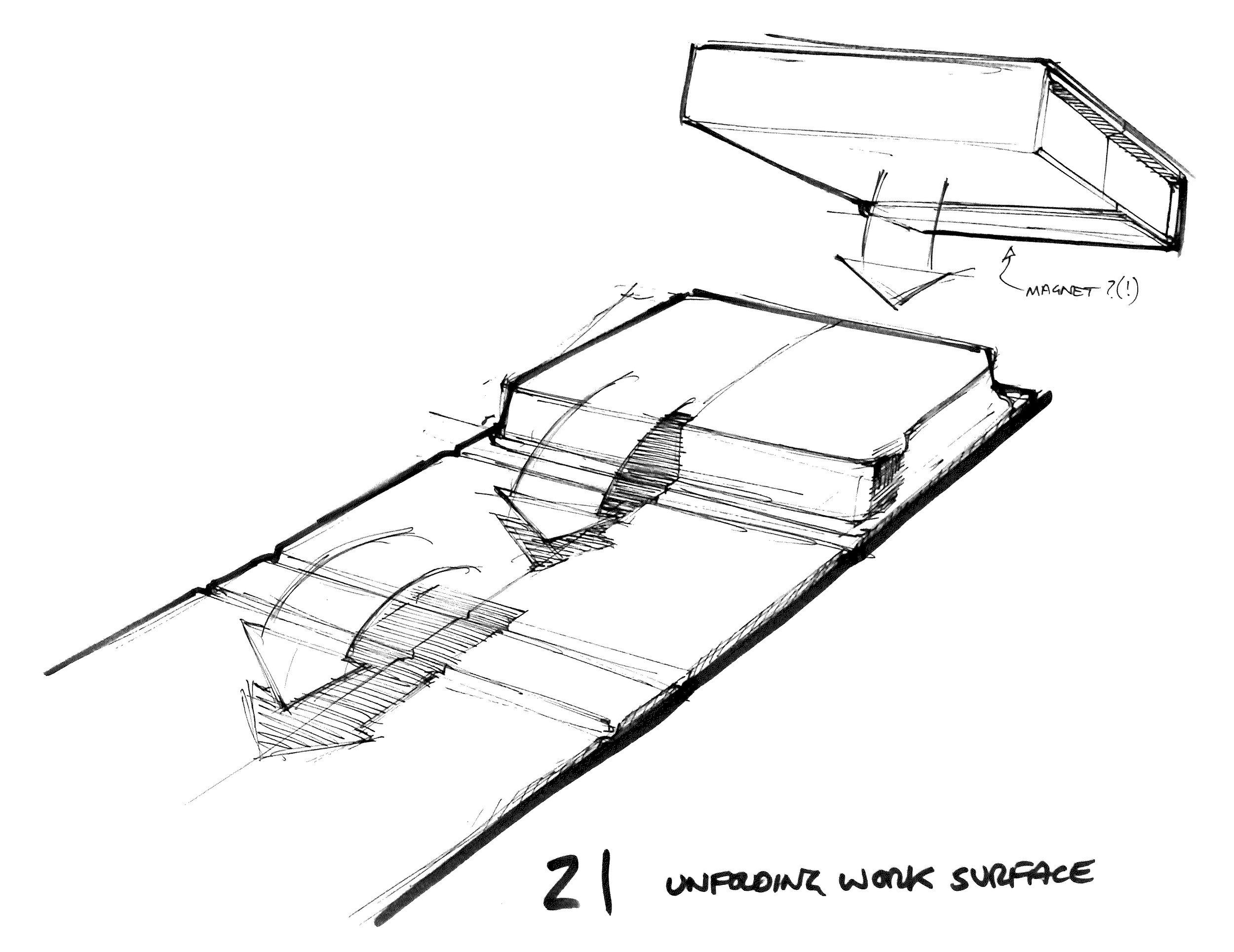

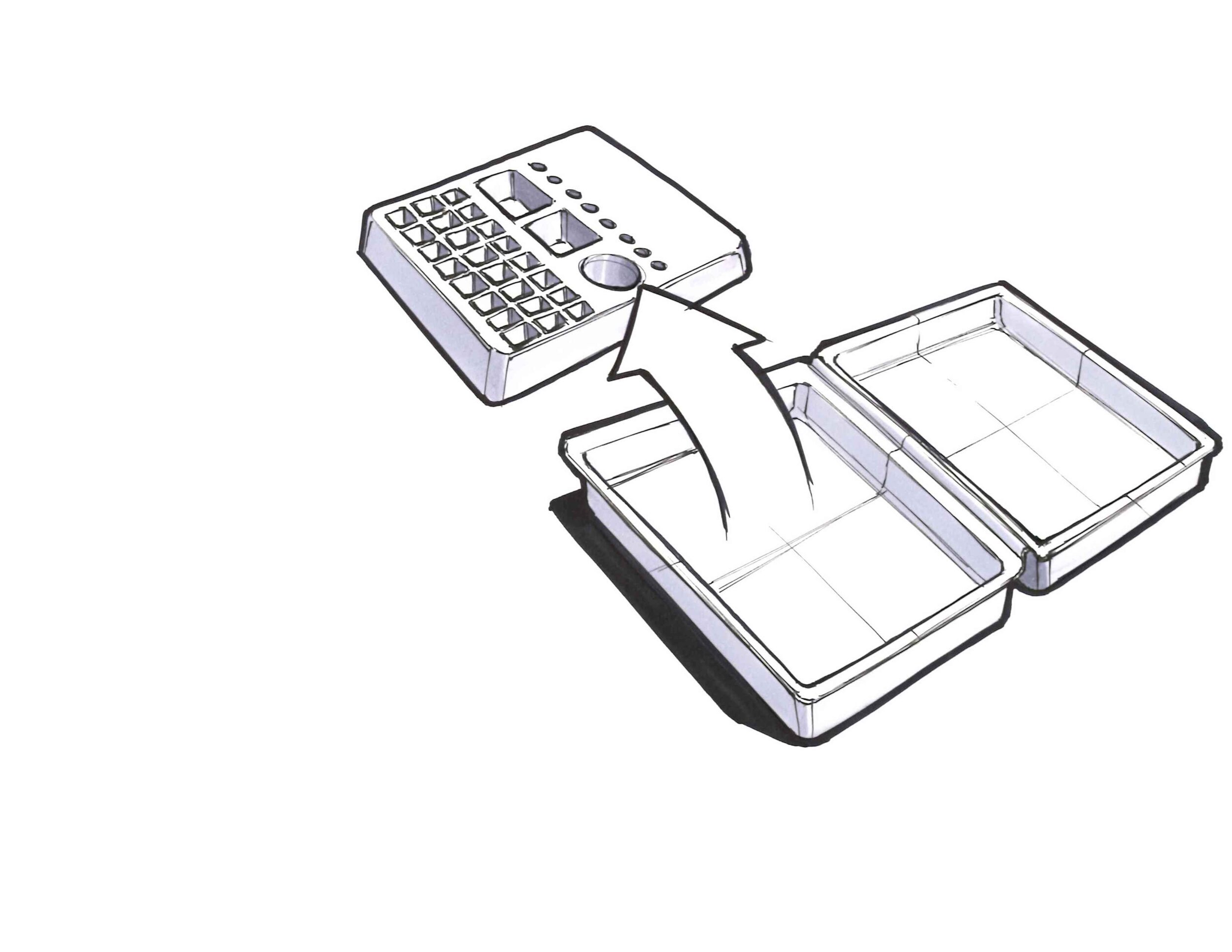

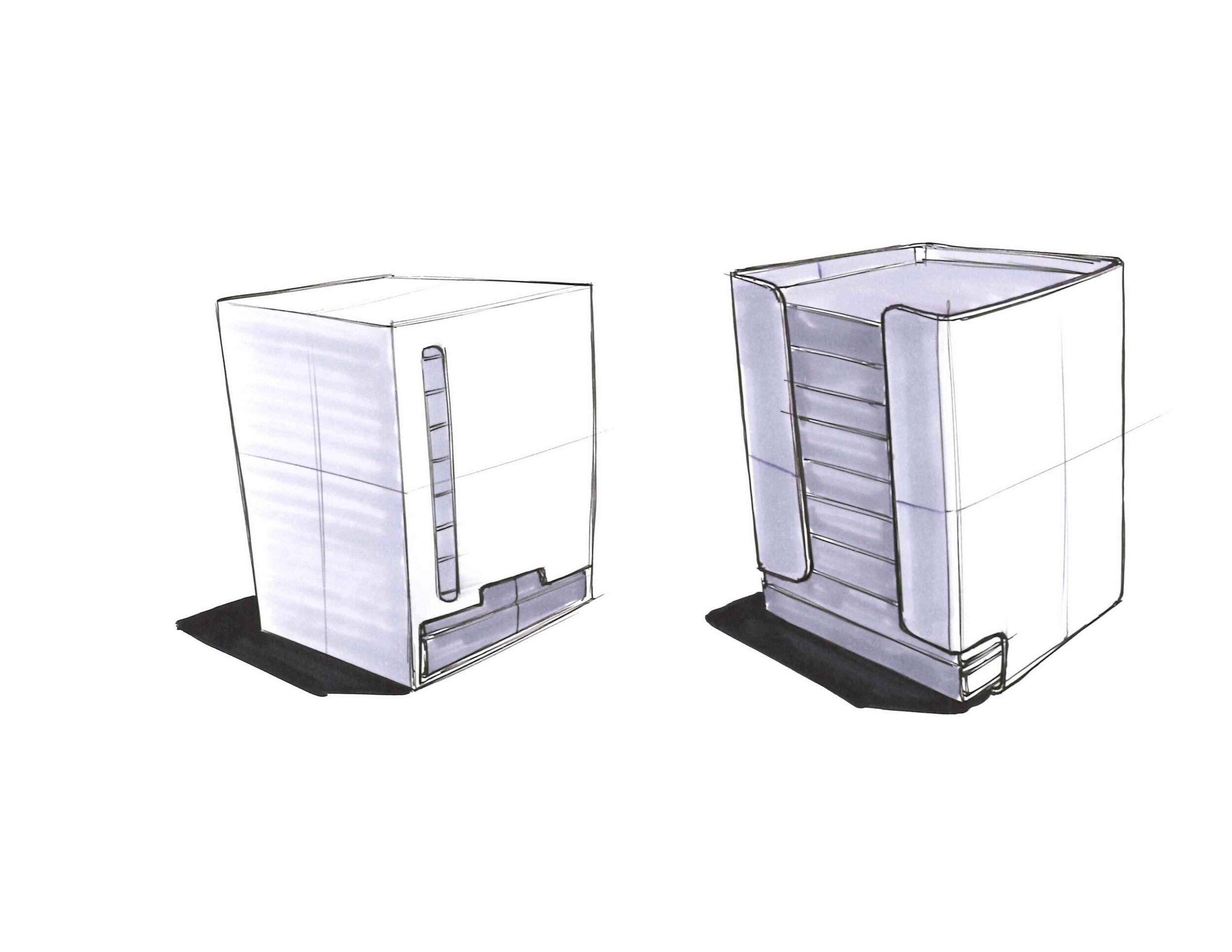

Rapid Ideation

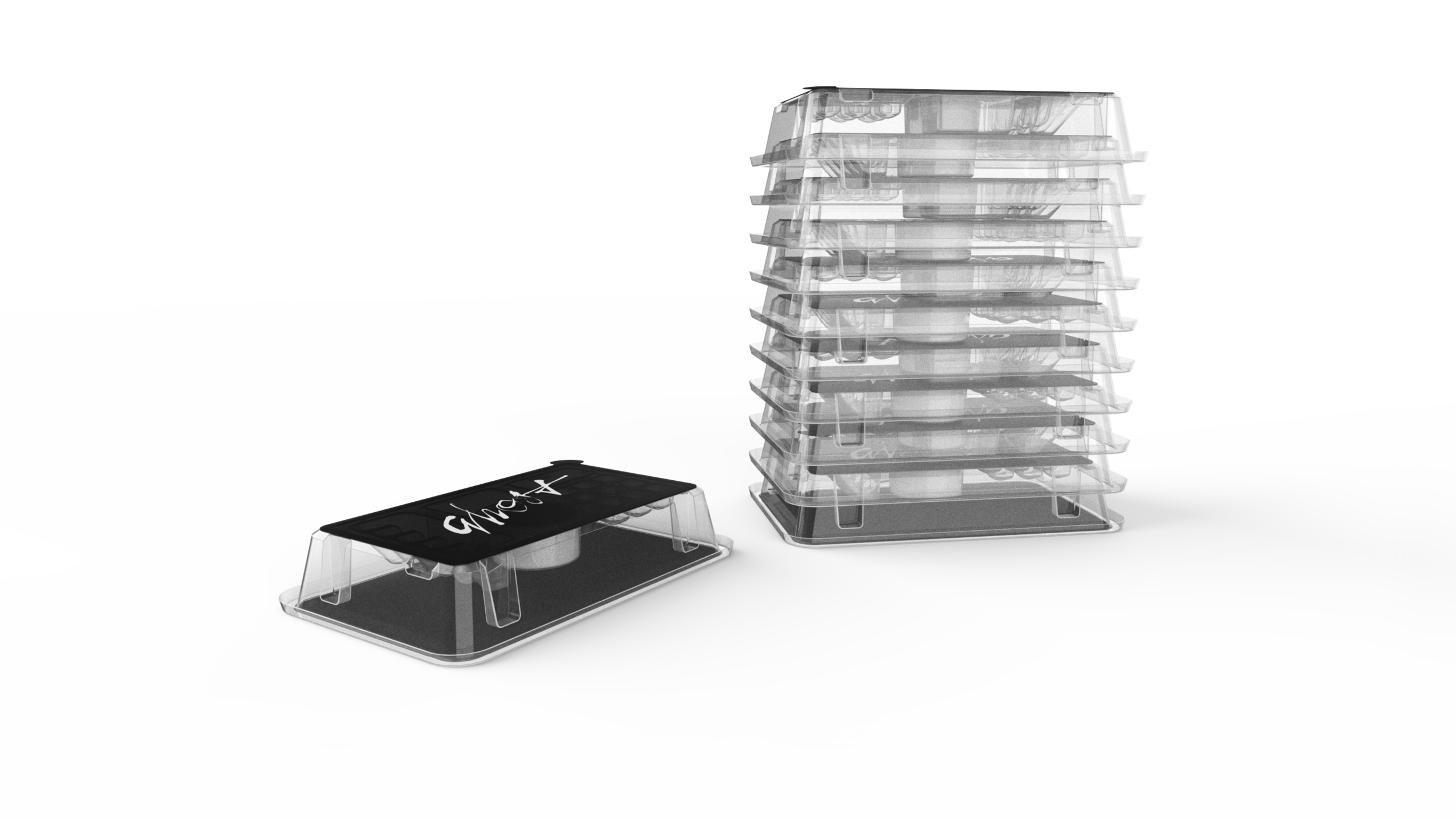

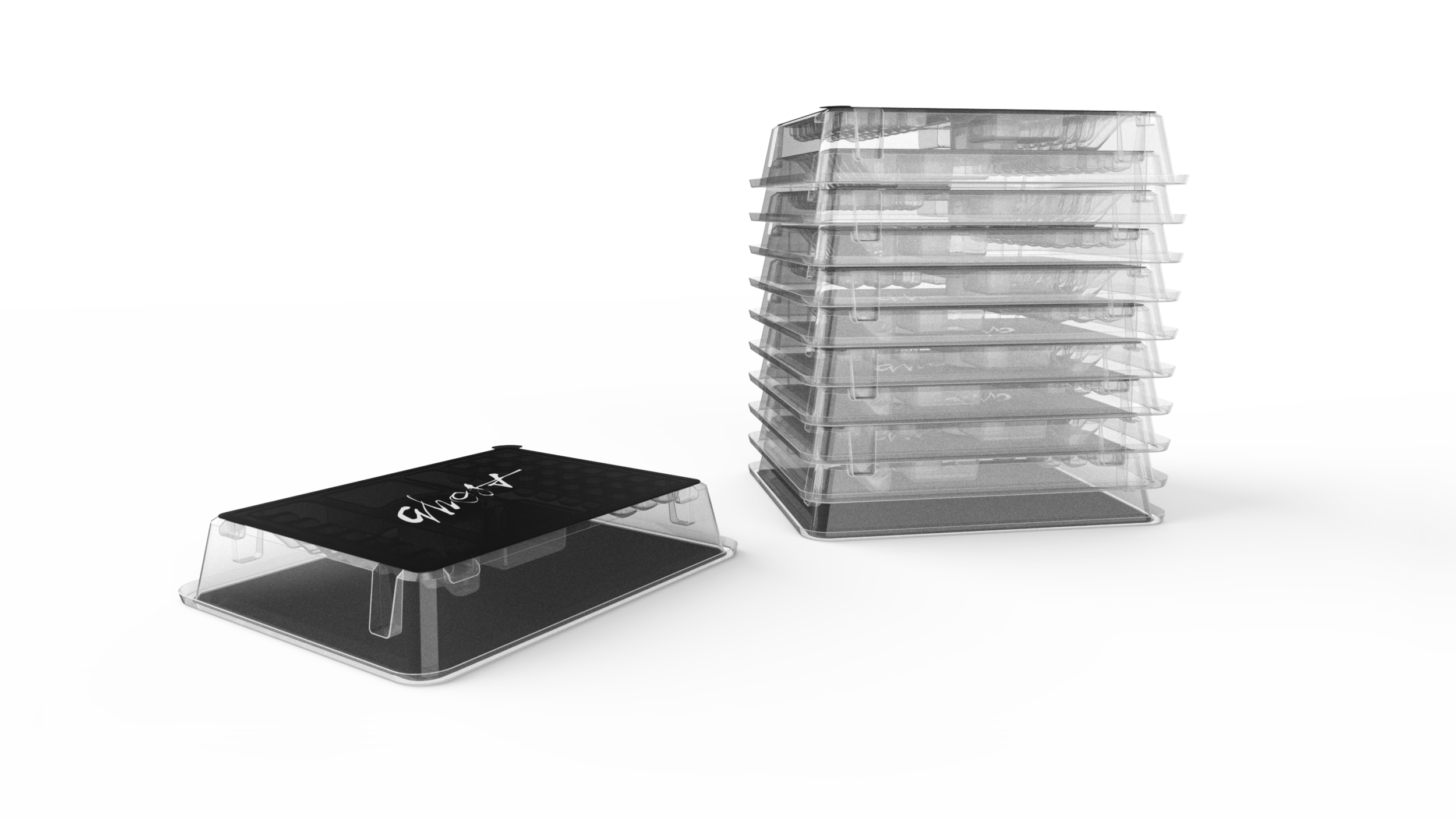

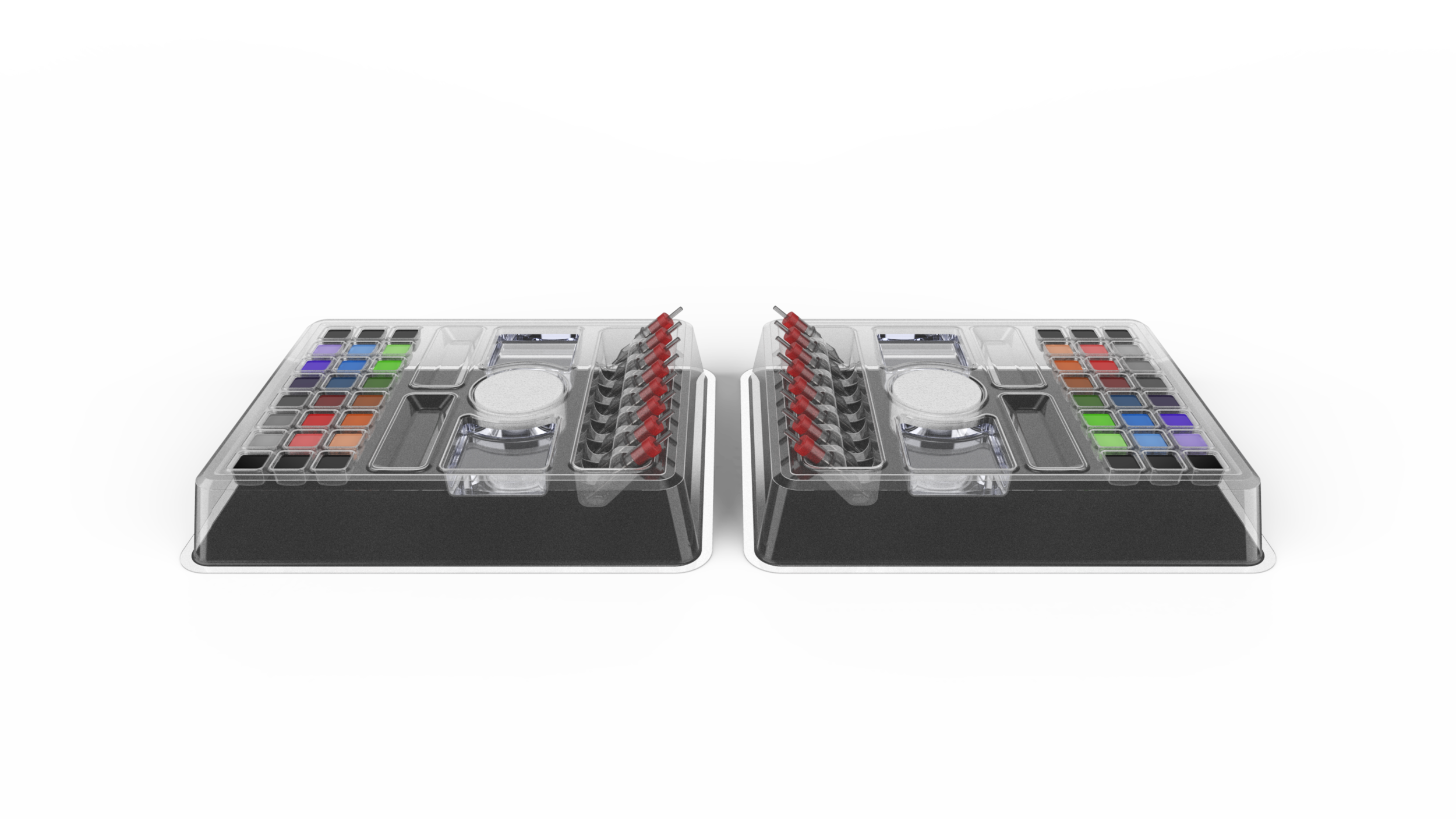

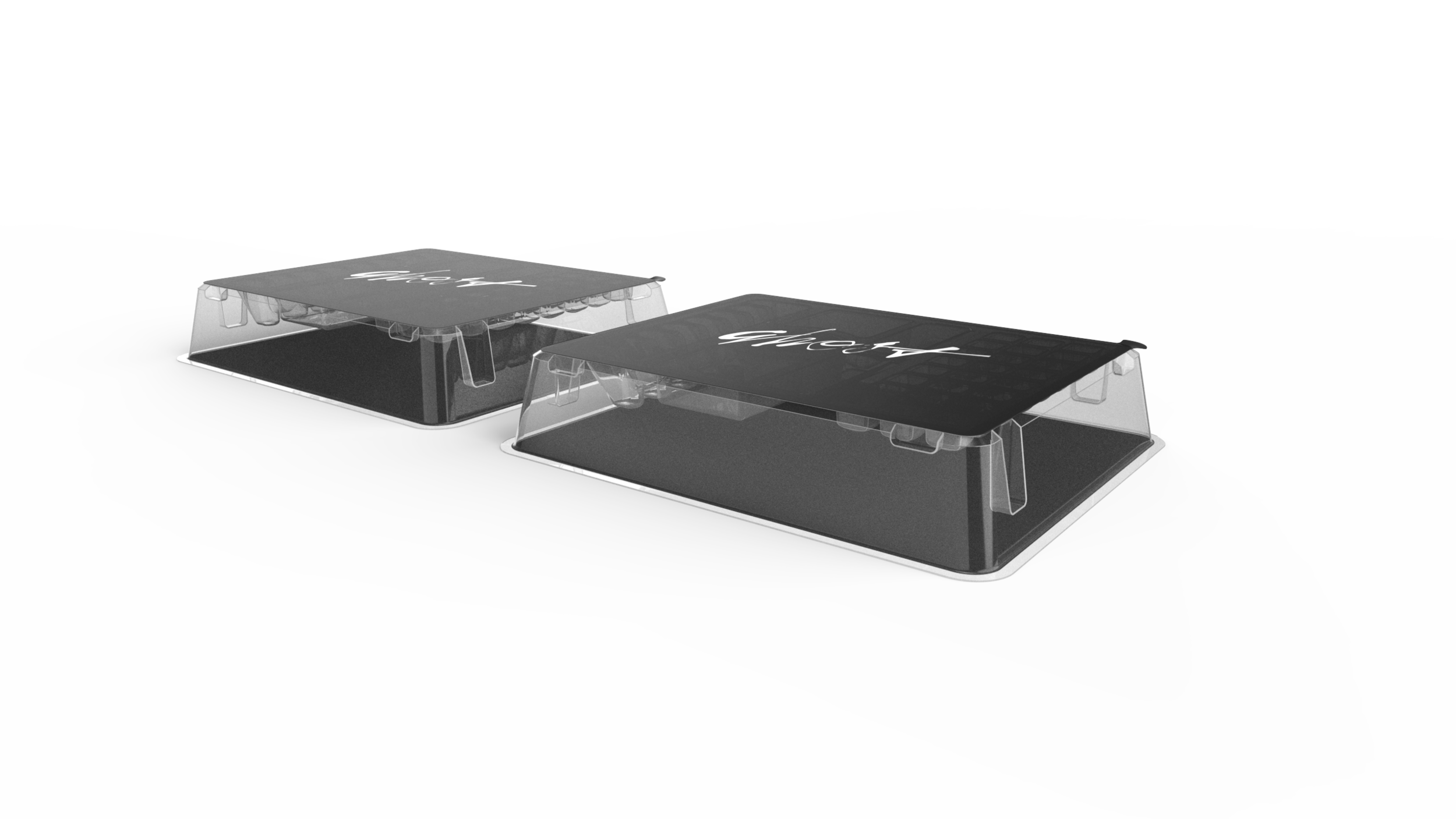

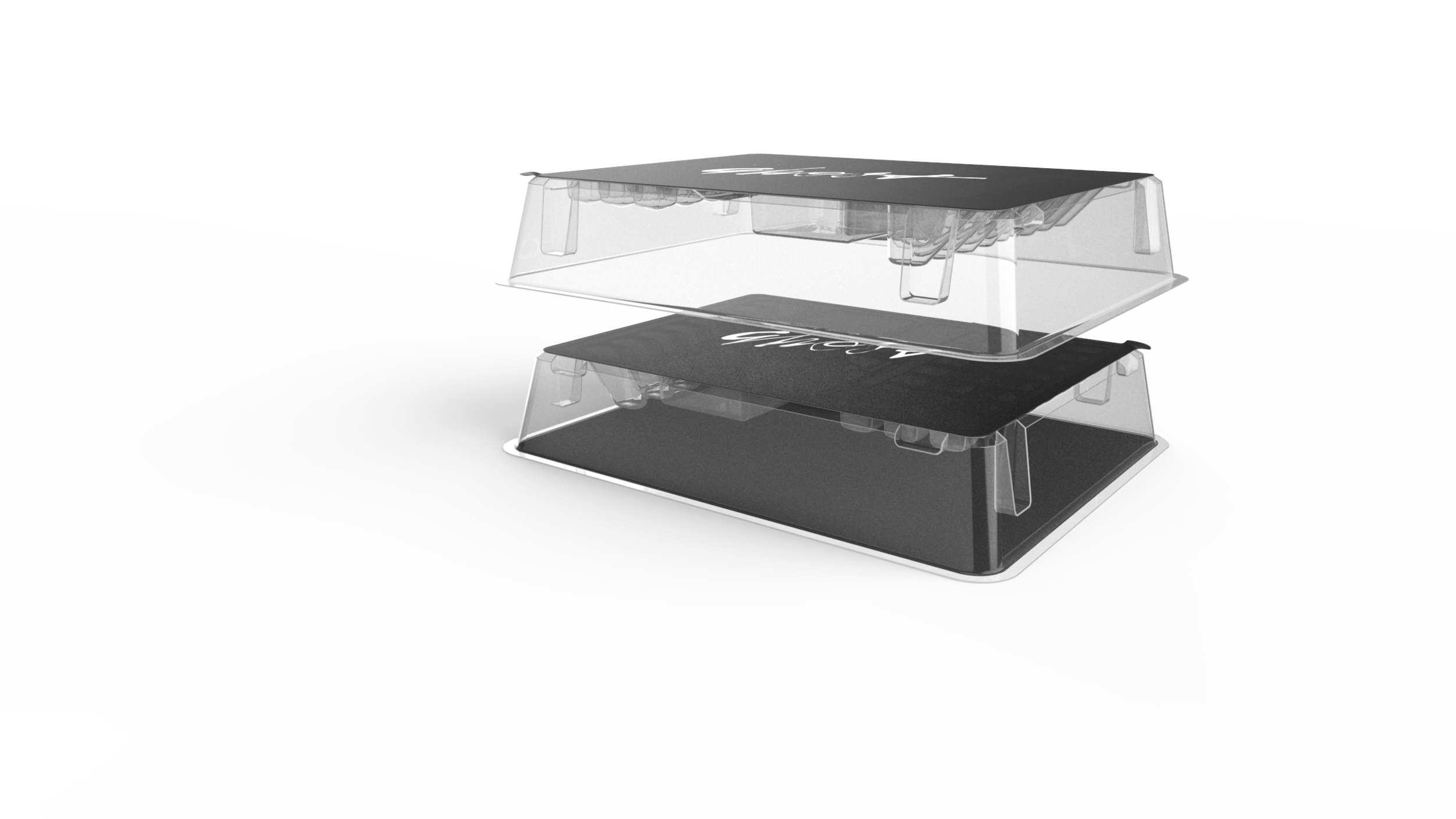

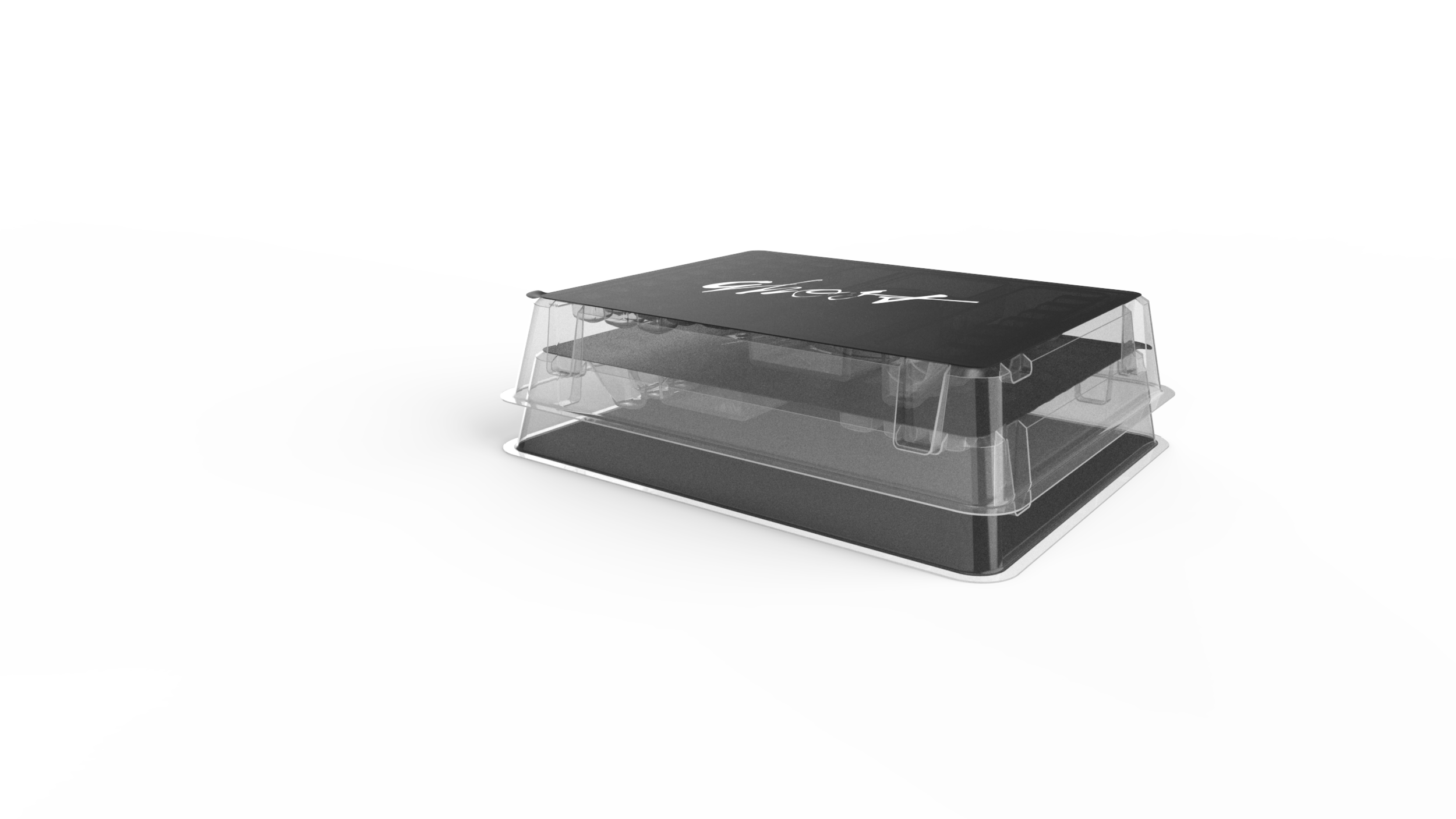

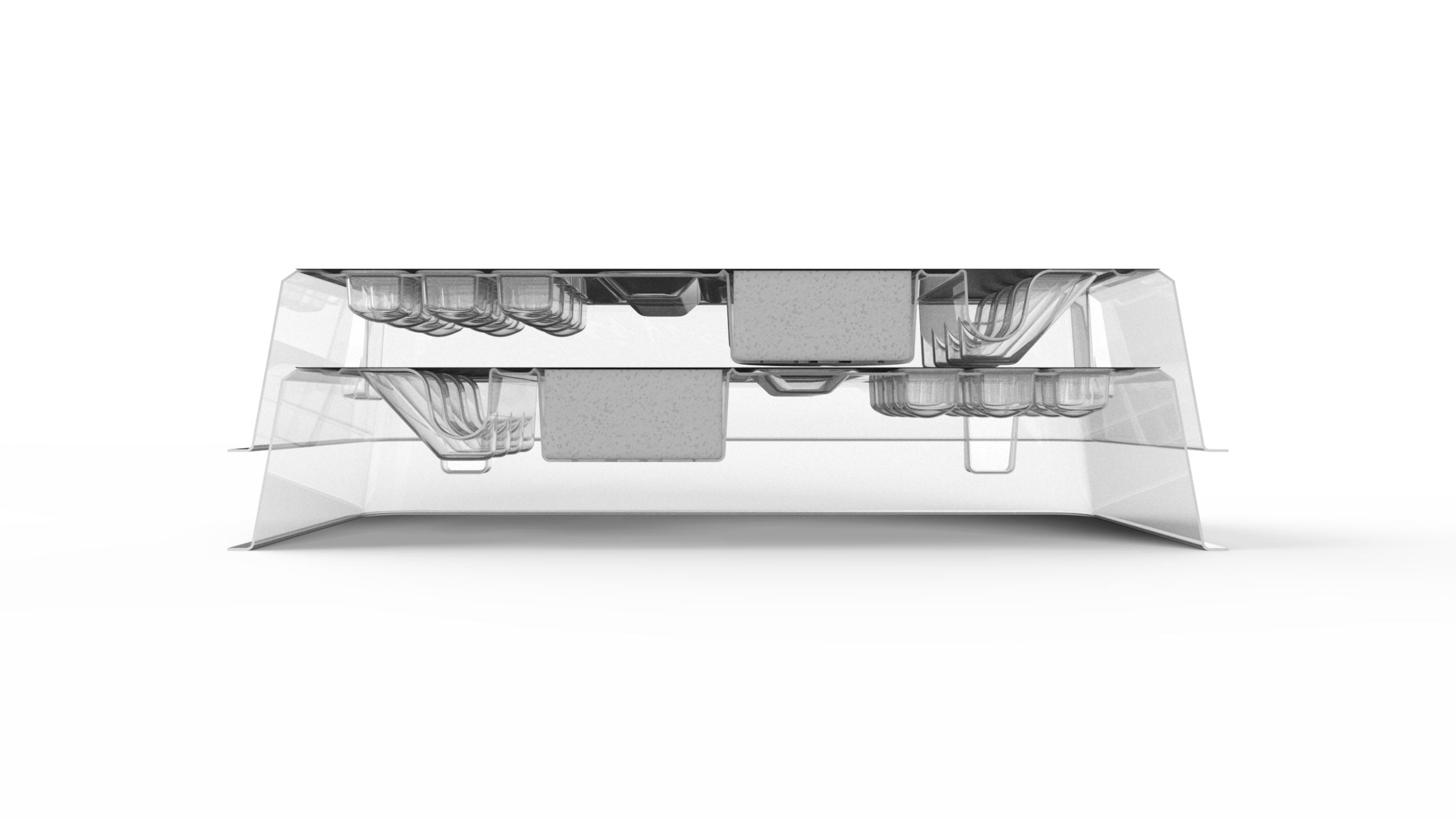

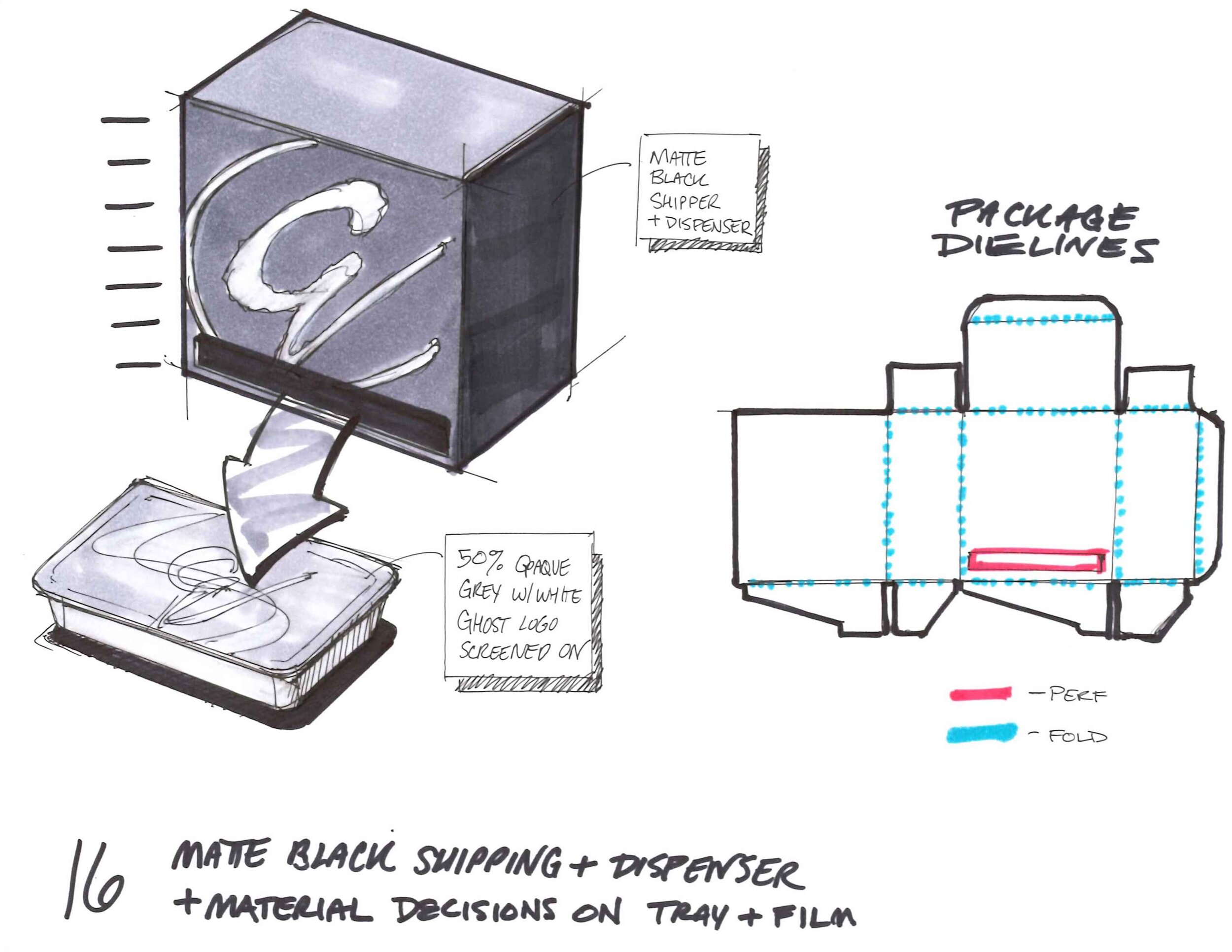

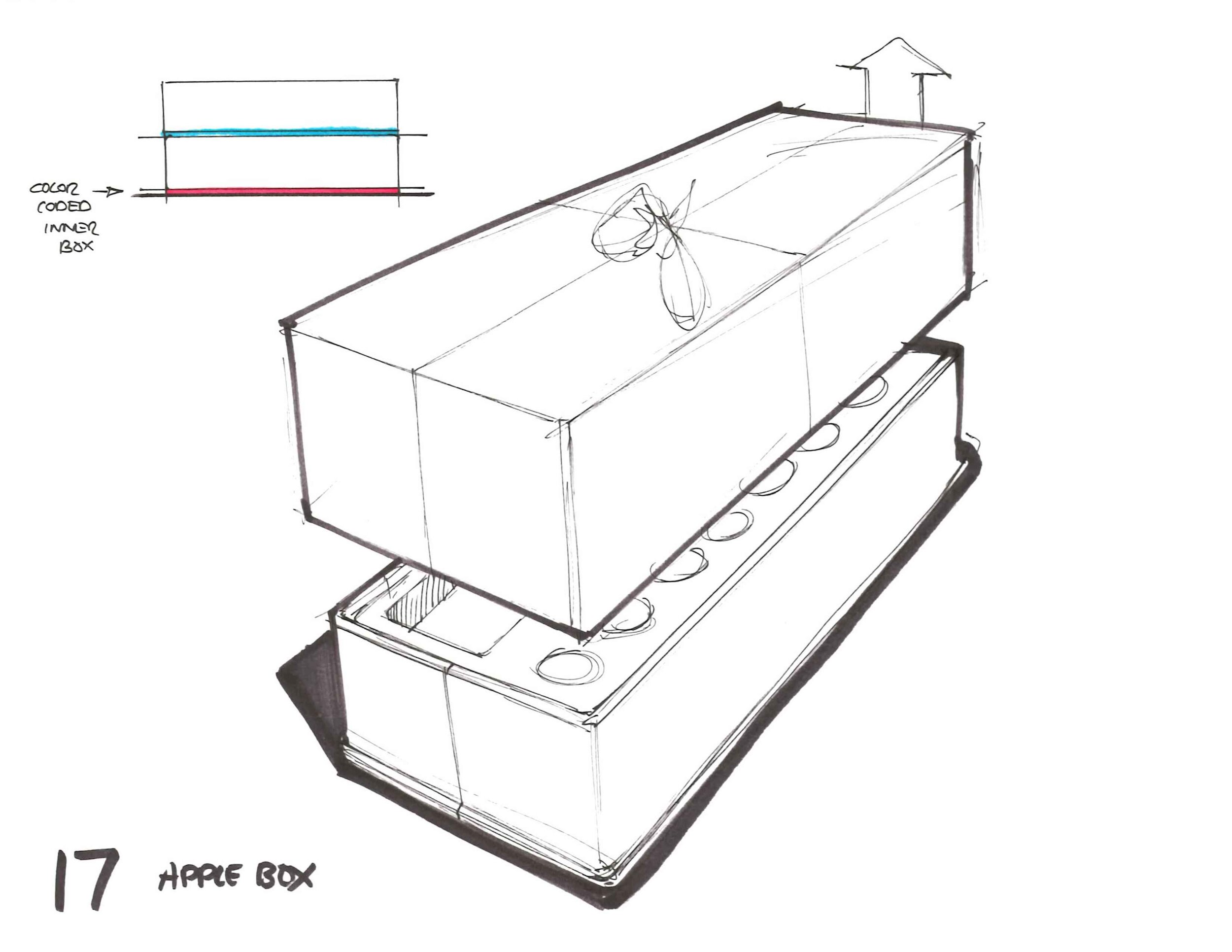

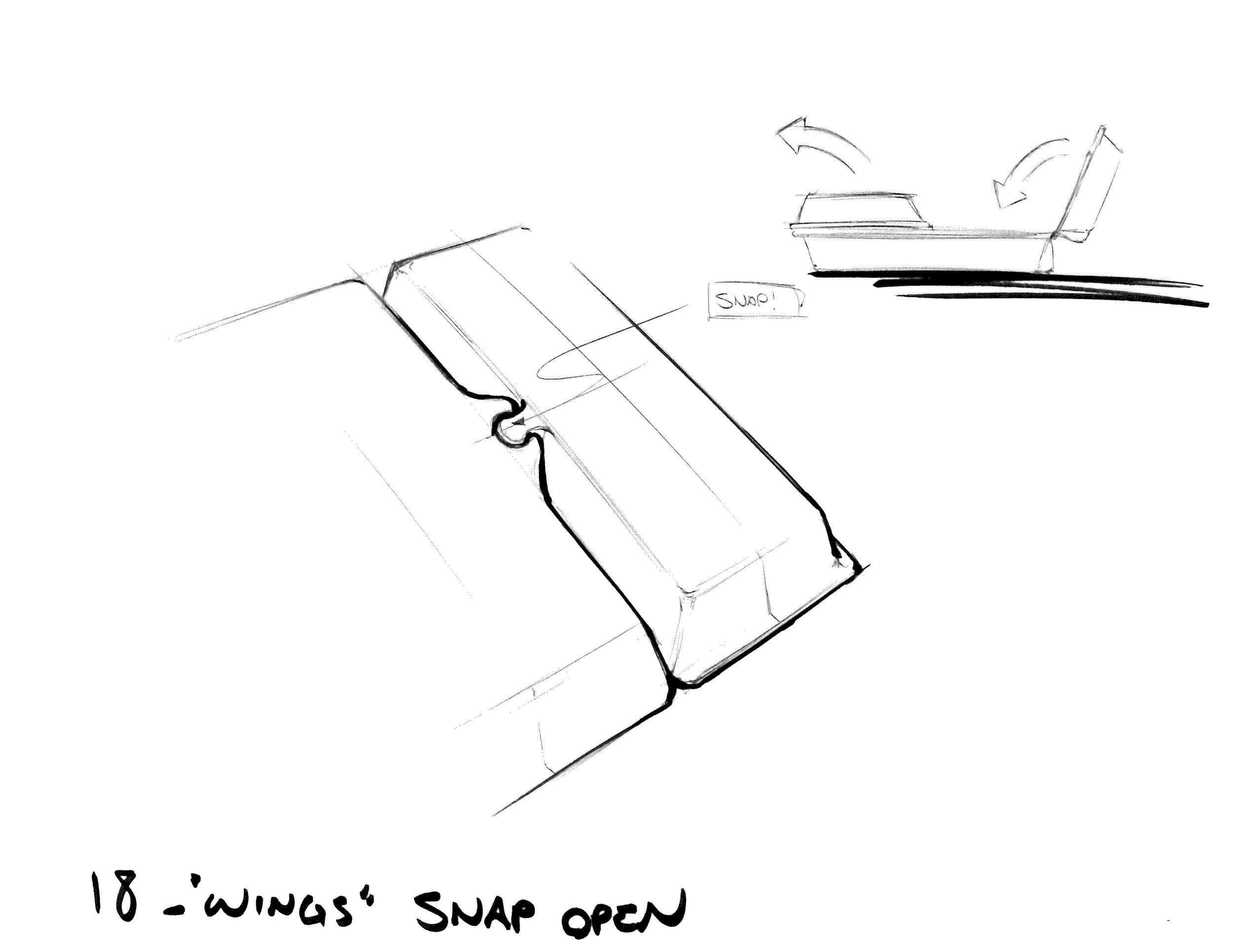

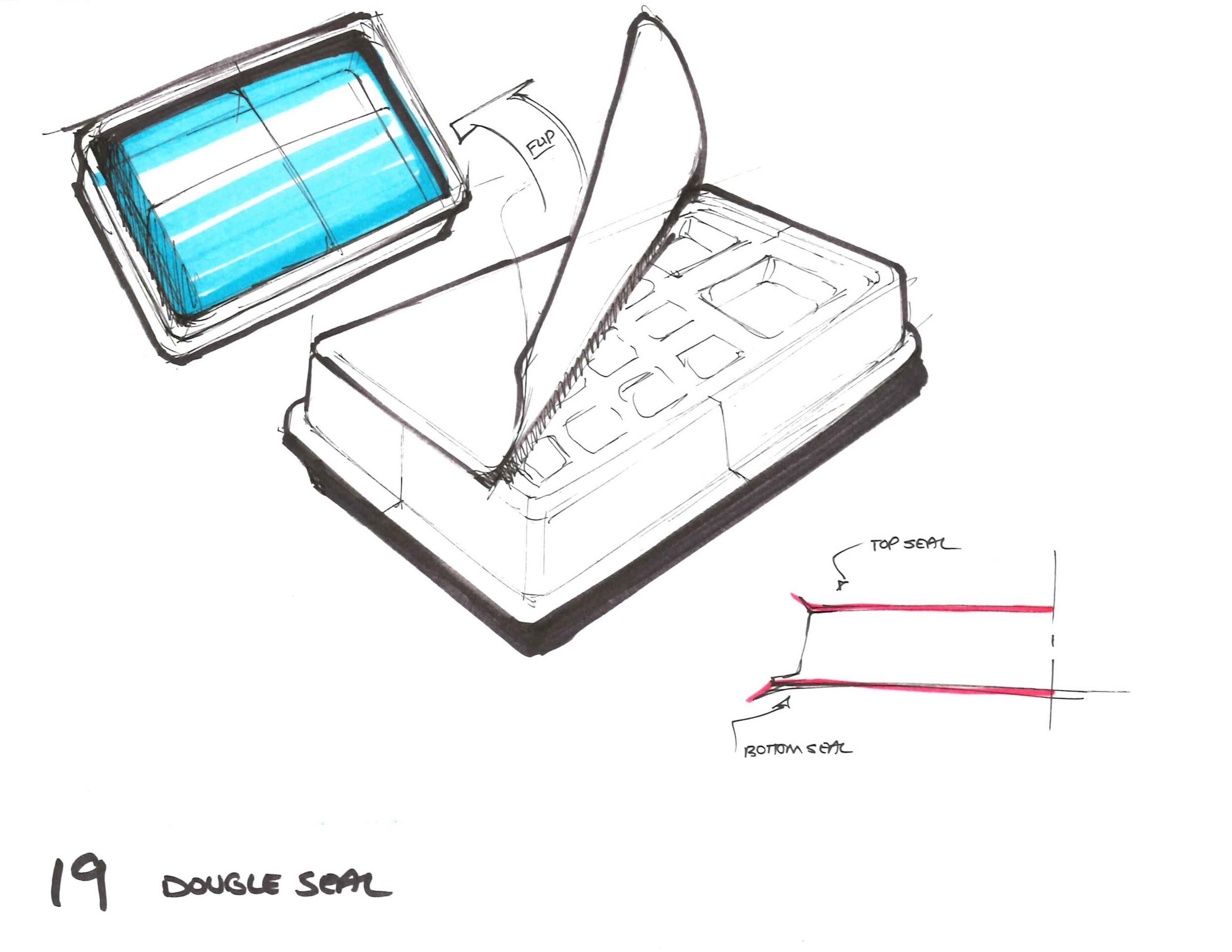

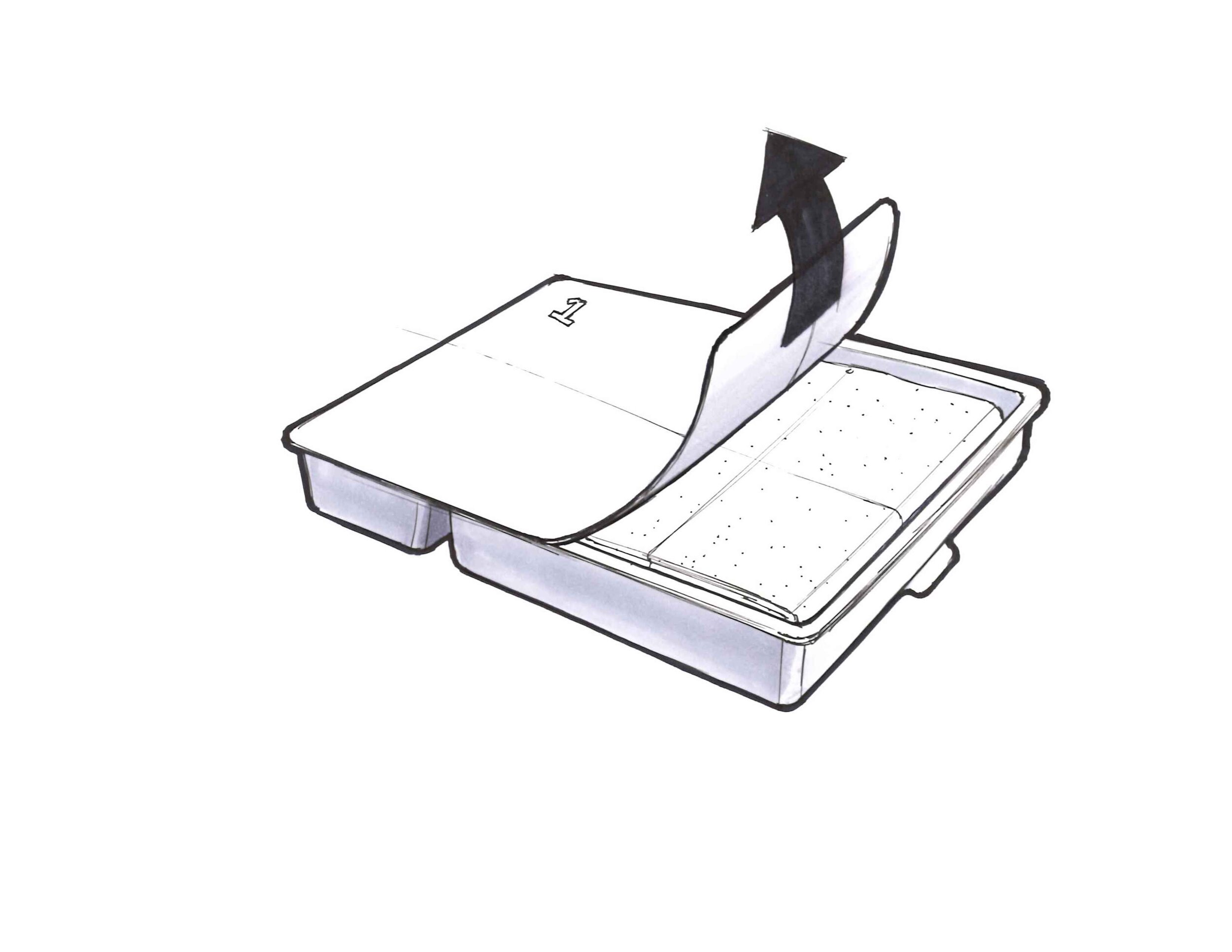

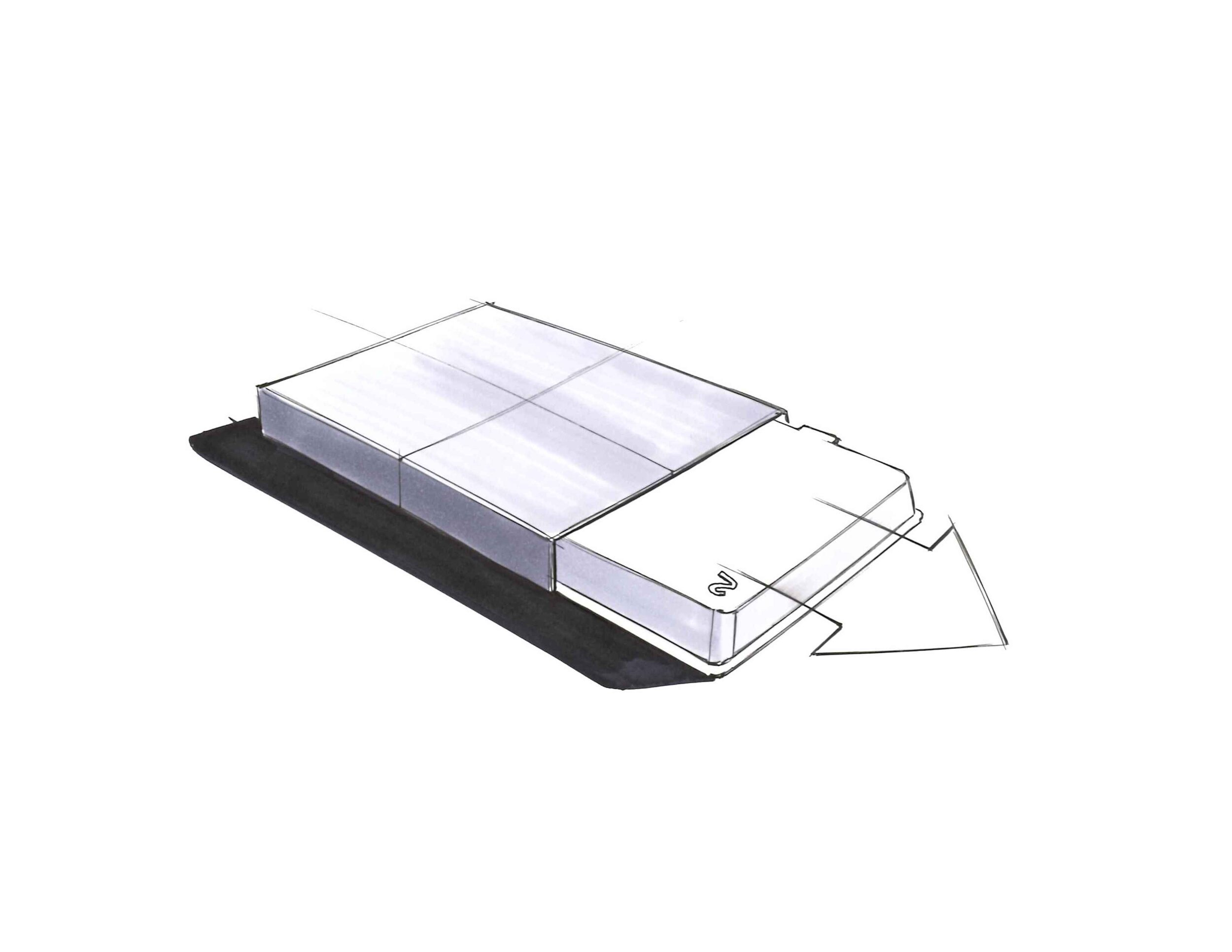

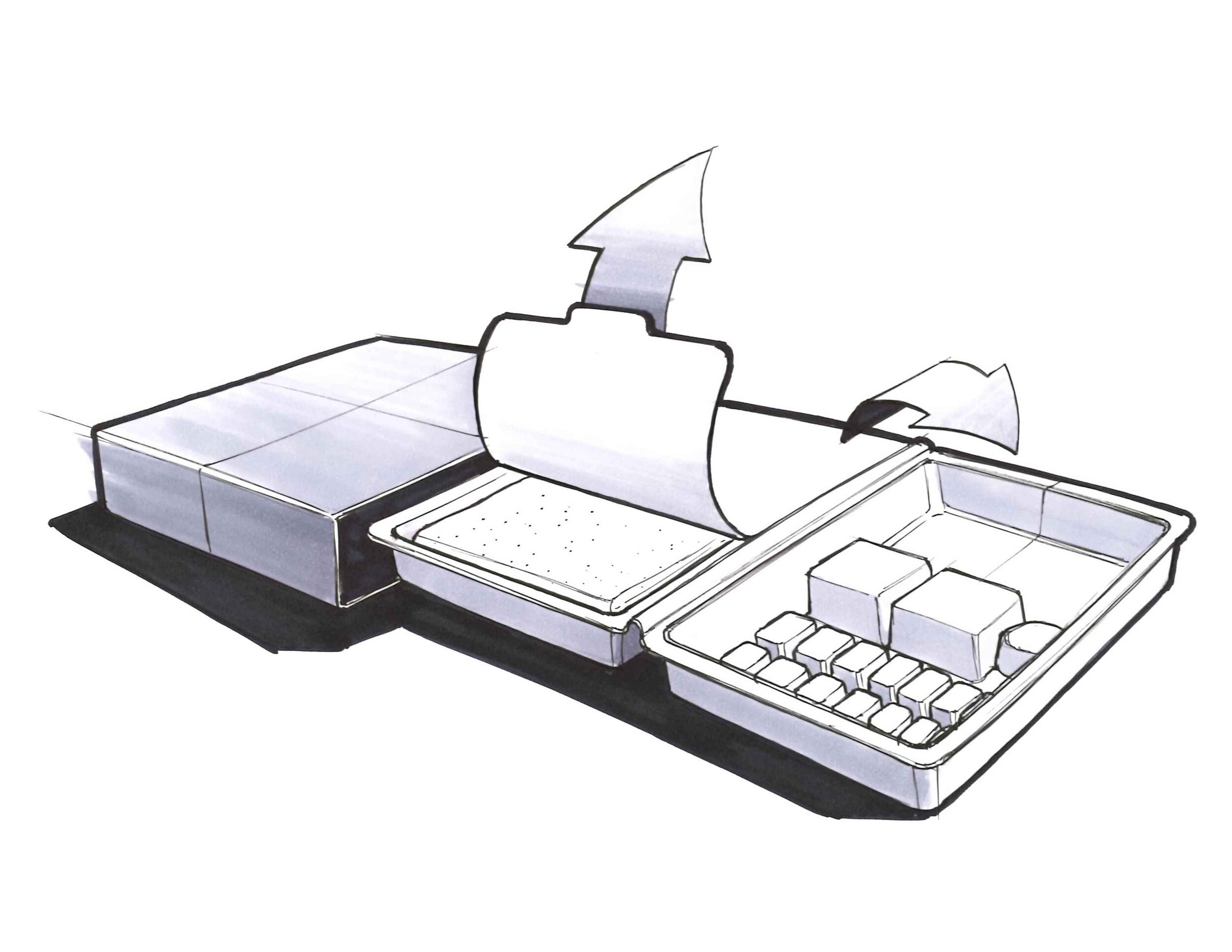

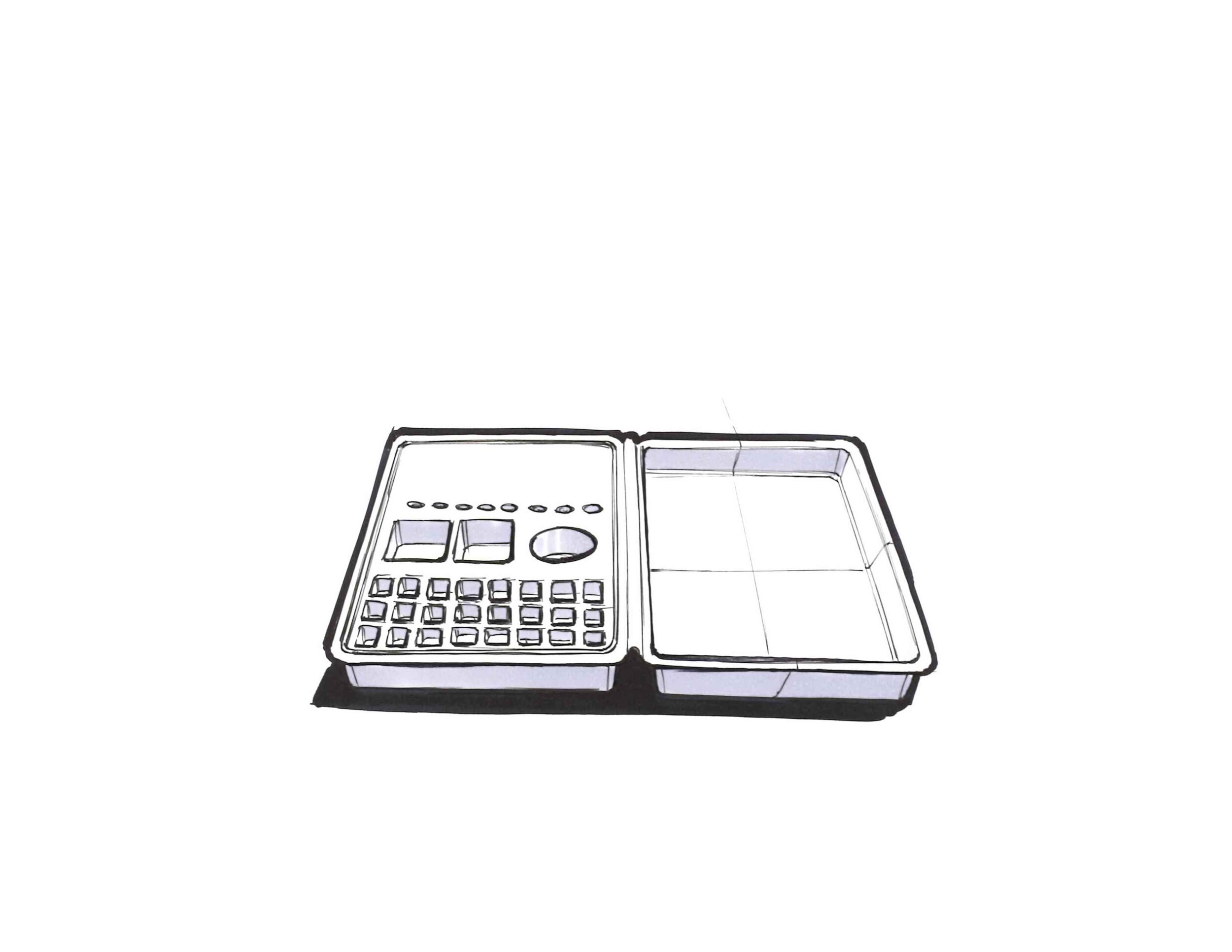

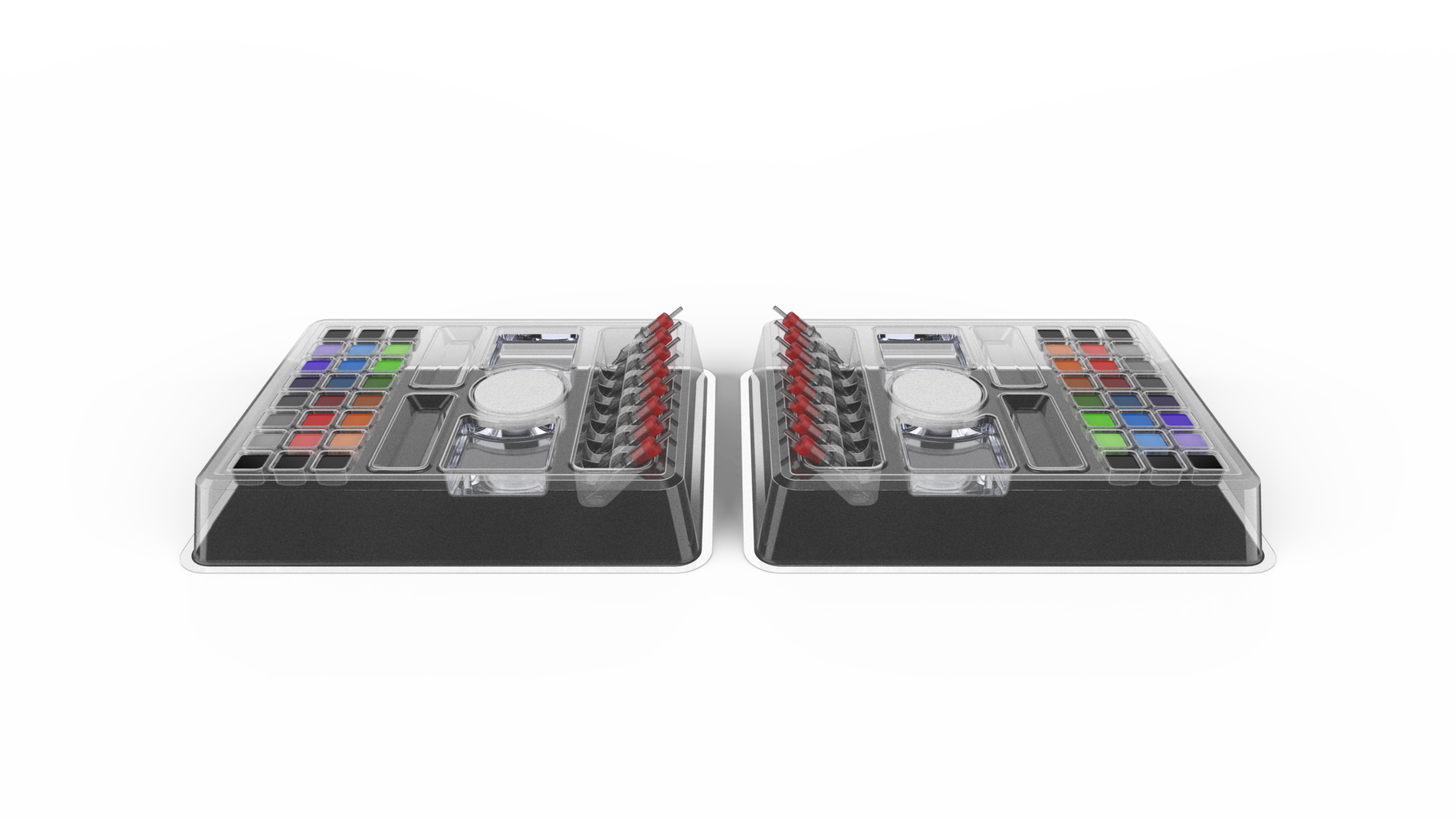

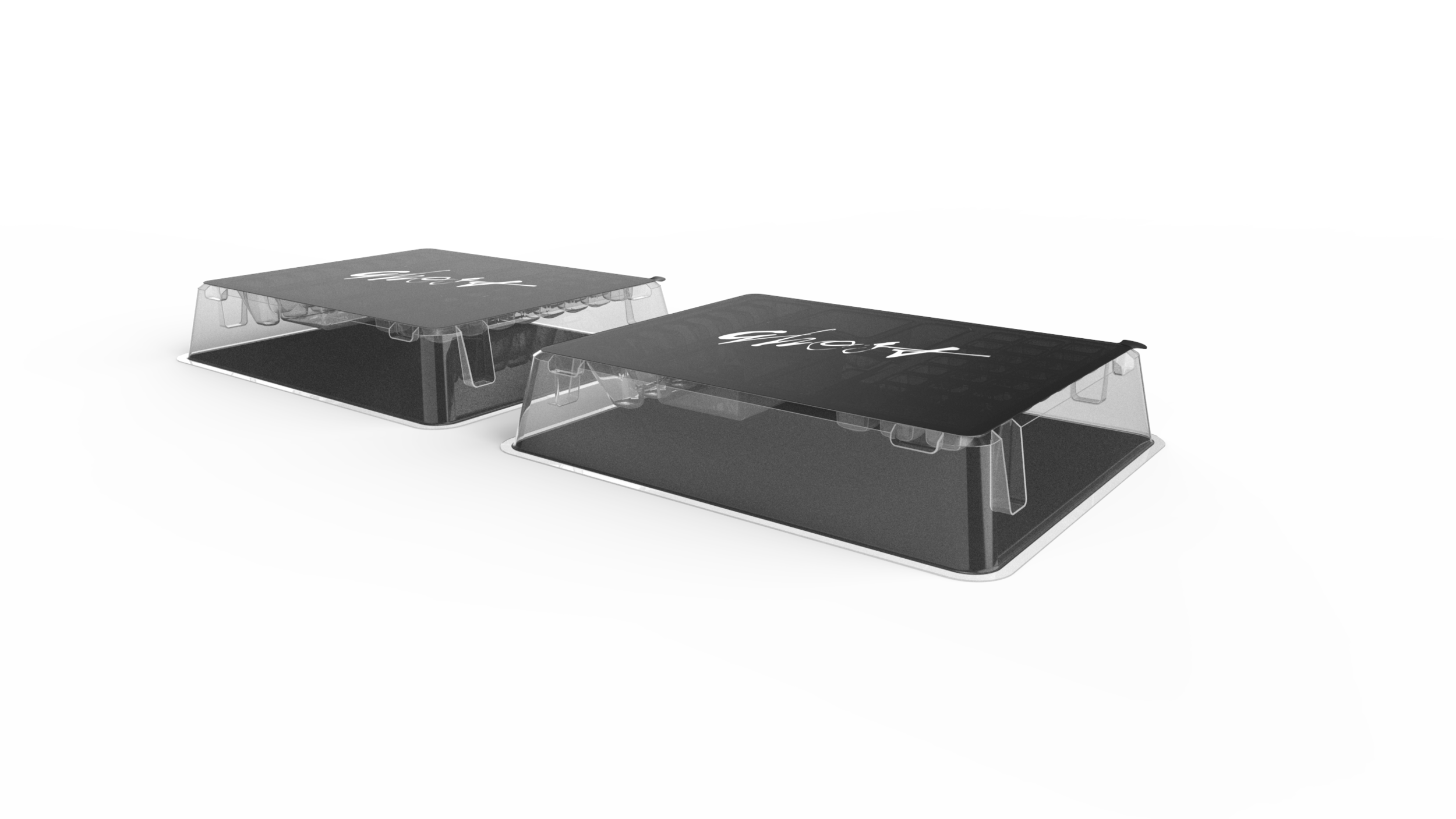

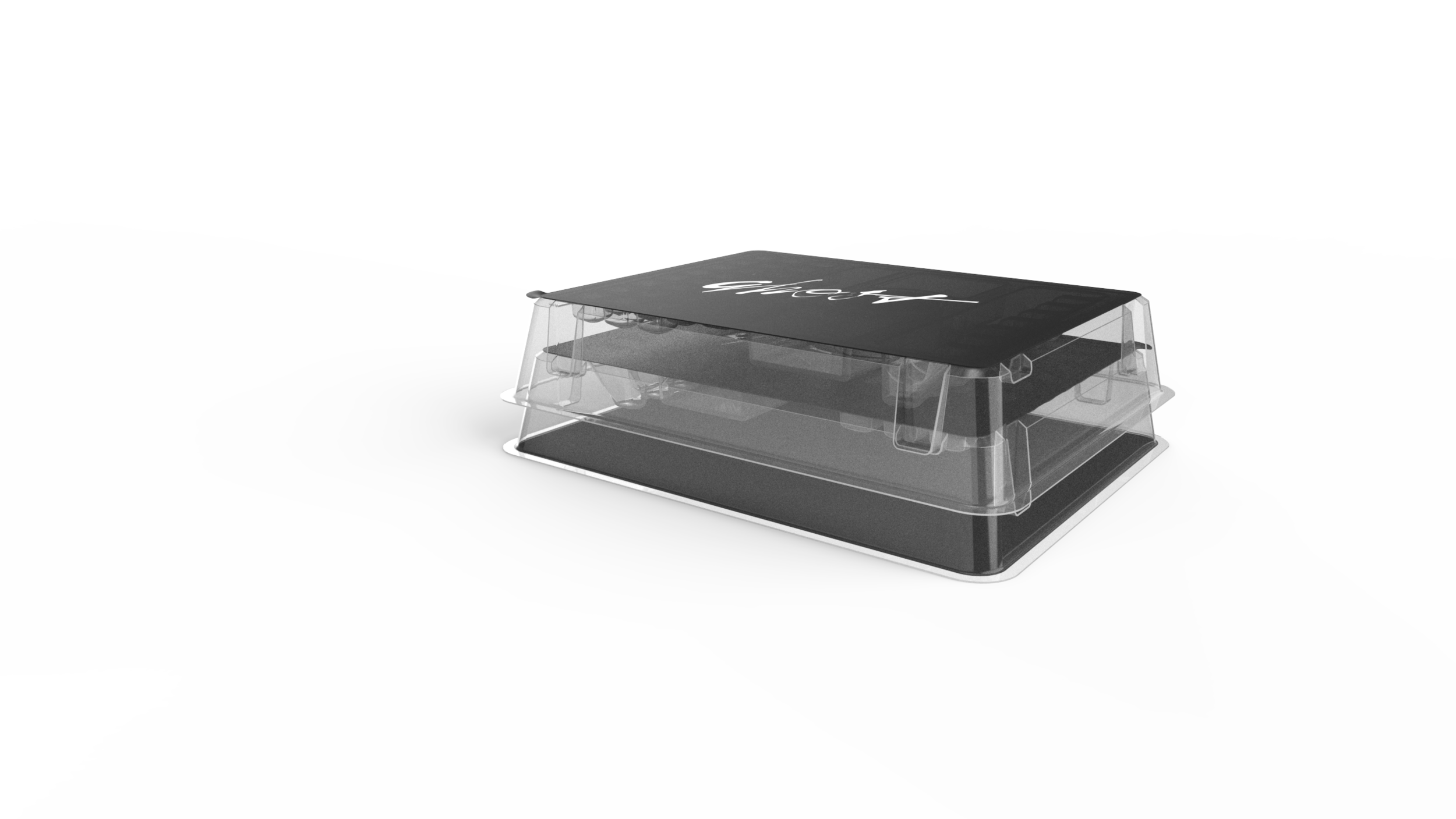

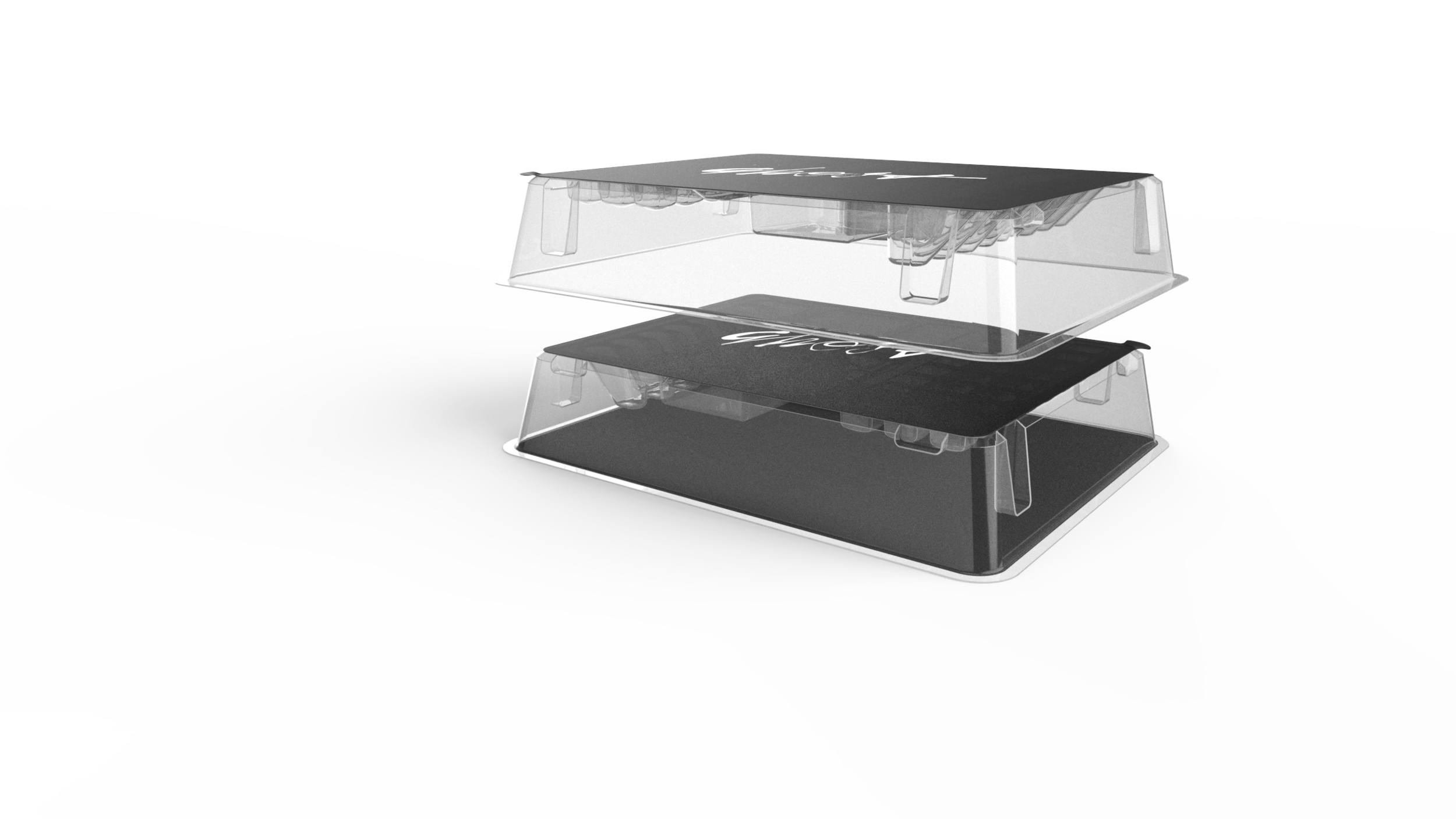

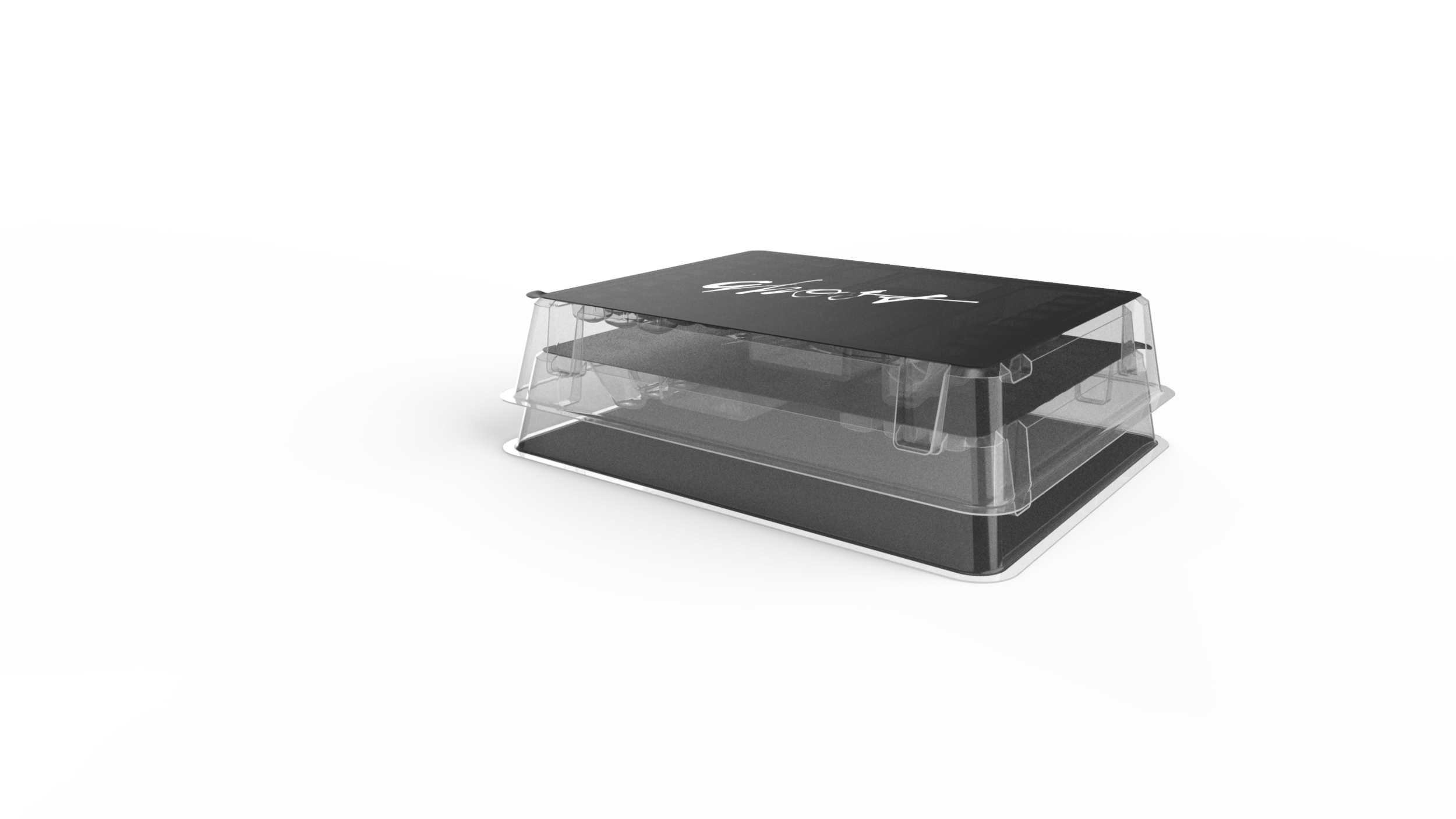

An initial round of live concept sketches were developed collaboratively in a single (T1) ideation session. At the close of the meeting, features from several sketches were combined into a small handful of concepts that were illustrated the following day. From those, a single concept was selected for 3D development. Just days later, the Ghost team was armed with an FDM model of their device for testing and refinement. After a round of CAD refinement, the design was sent to a local prototyping shop who produced functional thermo-formed prototypes for use at an upcoming tattoo exhibition.

4 Hours

8 Hours

72 Hours

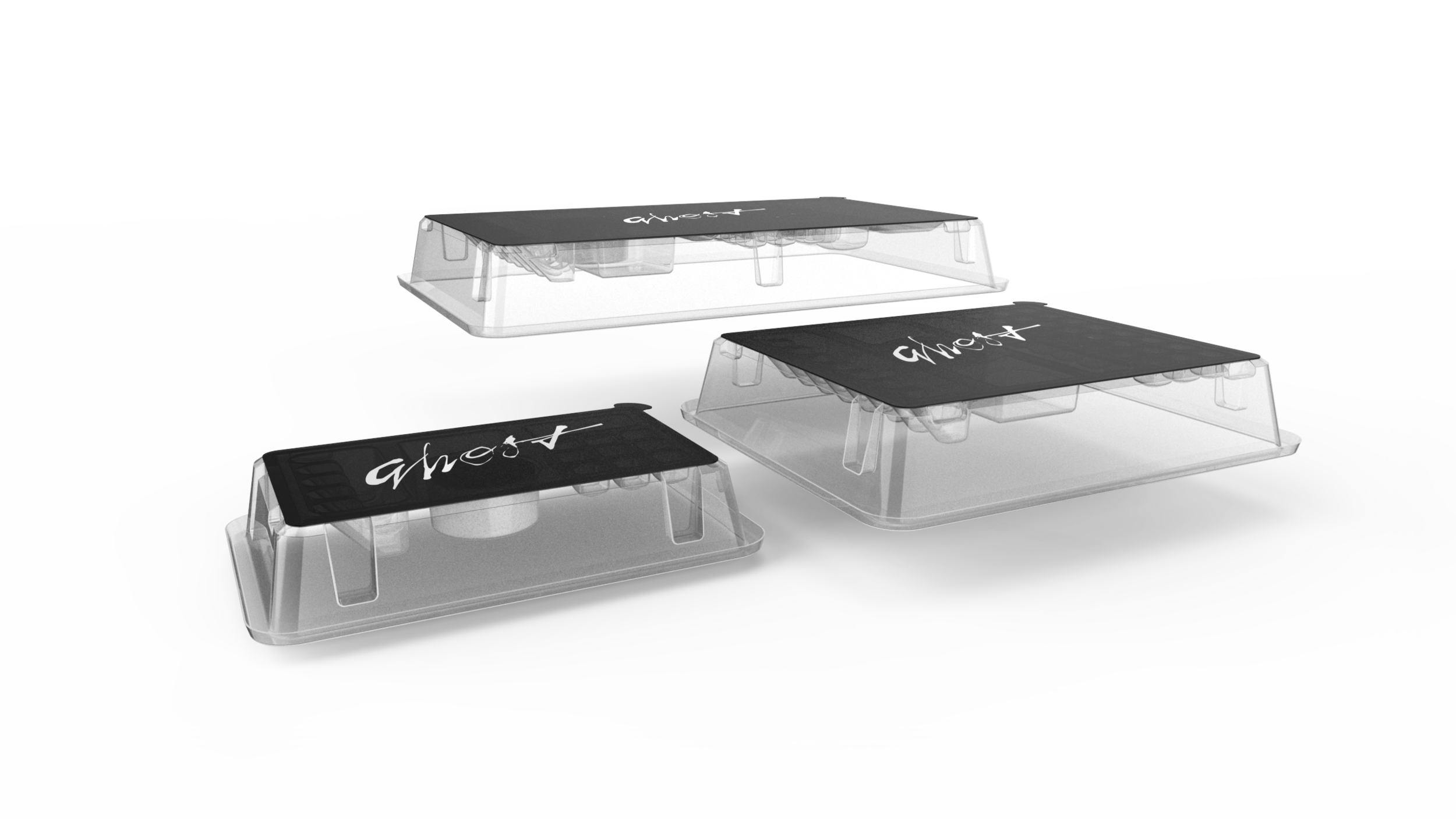

Excerpt from www.Ghost.ink

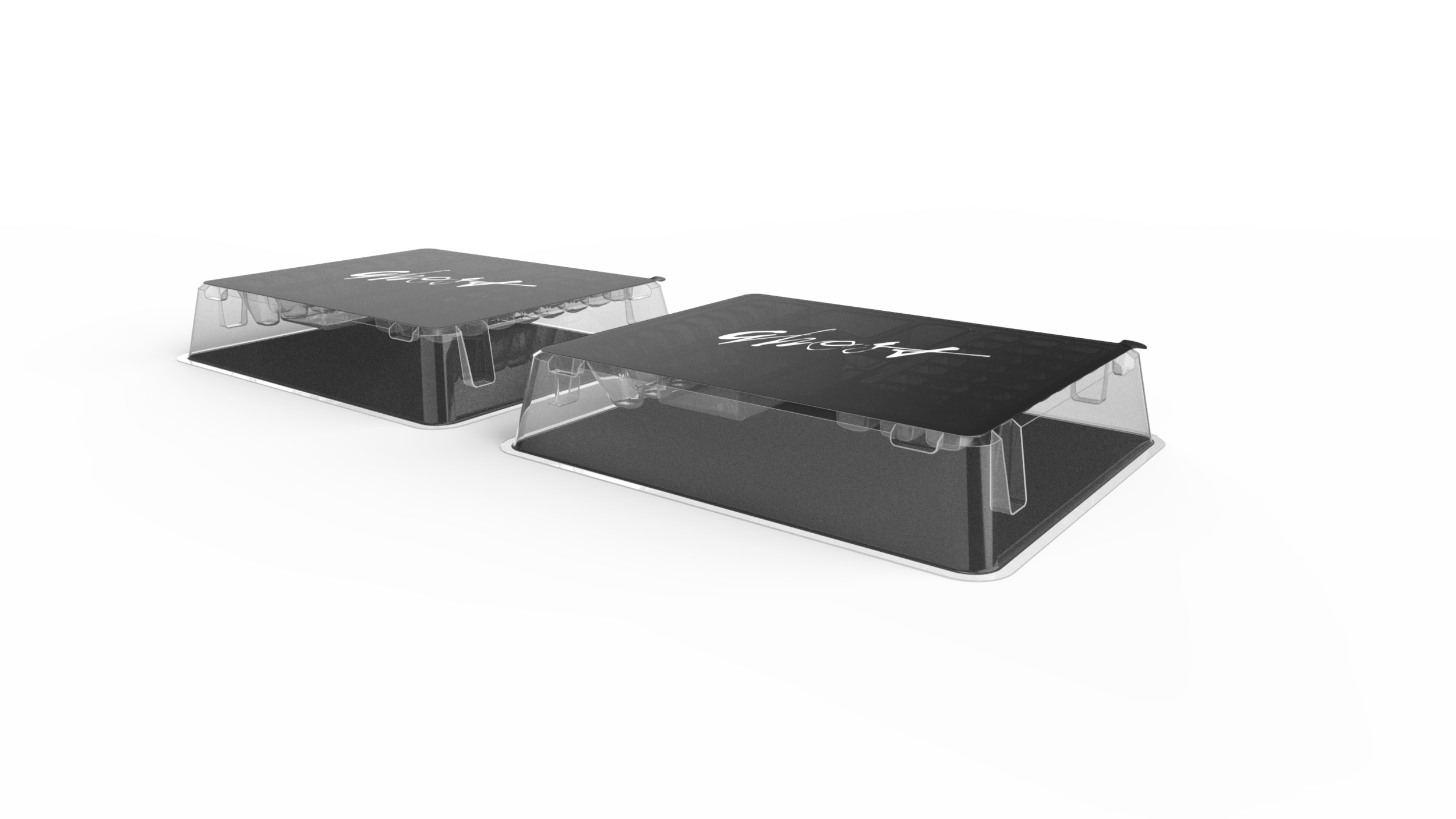

In the tattoo world, an inked masterpiece is reliant on the skills and talent of the artist, but an artist is nothing without their tools. Made for and by tattoo artists, Ghost custom set-up trays deliver quality products to meet the needs of tattoo industry professionals.

Krist Karloff is the artist behind this watercolor masterpiece and one of Ghost’s founders.

By way of Kentucky, Indiana and Florida, Bryan Kilby, Krist Karloff and Russell Van Schaick have come together and developed custom set-up trays with the artists’ needs in mind. Karloff and Van Schaick know the importance of ease and cost effectiveness when it comes to their work and Ghost custom set-up trays allows for a quick, easy and clean option.

Currently available in two sizes, customers can order standard kits, with the option of customizing their set-up with additional products of their liking to be wrapped and delivered in a functional tray. Ghost custom set-up trays make inventorying, physical set-up and disposal a breeze and are easy to pack for conventions or travel. The Ghost family puts artists first to facilitate their craft of which we have the utmost respect.